Submit feedback

NMP Solvent Recovery System Manufacturers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

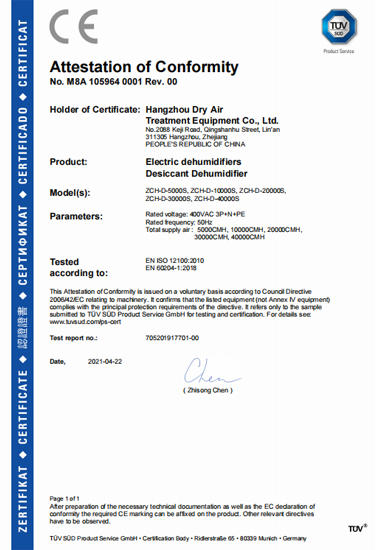

CE Certificate

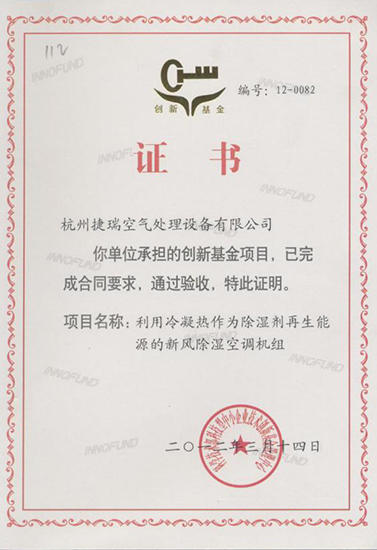

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

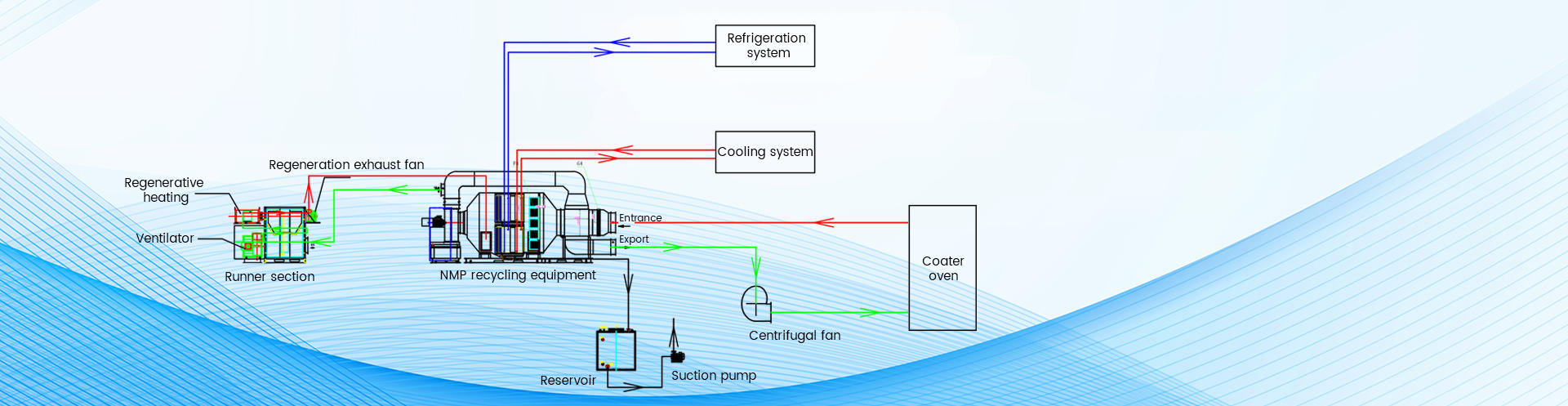

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

The Functions of NMP Solvent Recovery System

NMP (N-Methyl-2-Pyrrolidone) is a commonly used solvent in various industrial applications such as the petrochemical, pharmaceutical, and electronics industries. However, NMP is also known to be a volatile organic compound (VOC) and can pose a risk to the environment and human health if not handled properly.

Therefore, the NMP Solvent Recovery System is used to recover and recycle NMP from waste streams to reduce waste, minimize environmental impact, and save costs. The functions of the NMP Solvent Recovery System include:

Recovery of NMP: The primary function of the NMP Solvent Recovery System is to recover NMP from waste streams by separating it from other impurities and contaminants.

Purification of NMP: The recovered NMP may contain impurities that need to be removed before it can be reused. The NMP Solvent Recovery System purifies the recovered NMP to ensure it meets the required quality standards.

Recycling of NMP: Once the NMP is purified, it can be reused in the same process, reducing the need for new solvent and minimizing waste generation.

Energy savings: The NMP Solvent Recovery System can also help save energy by reducing the amount of NMP that needs to be produced and transported, which in turn reduces the energy required to produce and transport the solvent.

Cost savings: By recovering and recycling NMP, companies can reduce their costs associated with purchasing new solvent and disposing of waste, leading to significant cost savings over time

Overall, the NMP Solvent Recovery System plays a crucial role in reducing waste, minimizing environmental impact, and saving costs in various industrial applications that use NMP as a solvent.

The Importance of NMP Solvent Recovery System

NMP (N-methyl-2-pyrrolidone) is a solvent commonly used in various industrial processes, such as in the manufacturing of electronics, pharmaceuticals, and chemicals. However, NMP is also a hazardous substance that can cause harm to human health and the environment if not handled properly. This is where the importance of NMP solvent recovery systems comes in. Here are some of the reasons why these systems are essential:

Environmental Protection: NMP is a volatile organic compound (VOC) that can contribute to air pollution and the formation of ground-level ozone. NMP solvent recovery systems help to reduce the emission of NMP into the environment by recovering and recycling it, reducing the environmental impact of industrial processes.

Cost-Effective: NMP is a costly solvent, and its disposal can also be expensive. With an NMP solvent recovery system, the solvent can be recovered and recycled, reducing the need to purchase new solvent and lowering the disposal costs.

Compliance with Regulations: Many countries have regulations in place to control the emission of hazardous air pollutants, including NMP. Failure to comply with these regulations can result in fines and legal consequences. NMP solvent recovery systems can help companies comply with these regulations, avoiding legal and financial penalties.

Improved Safety: NMP is a hazardous substance that can cause health problems if not handled properly. Exposure to NMP can cause skin irritation, respiratory problems, and even reproductive issues. NMP solvent recovery systems can improve workplace safety by reducing the risk of exposure to NMP.

Overall, NMP solvent recovery systems play a crucial role in reducing the environmental impact of industrial processes, lowering costs, ensuring compliance with regulations, and improving workplace safety. Companies that use NMP should consider investing in these systems to reap these benefits.

English

English 简体中文

简体中文

View All

View All