Submit feedback

Pharmaceutical Chemicals Waste Gas Treatment Suppliers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

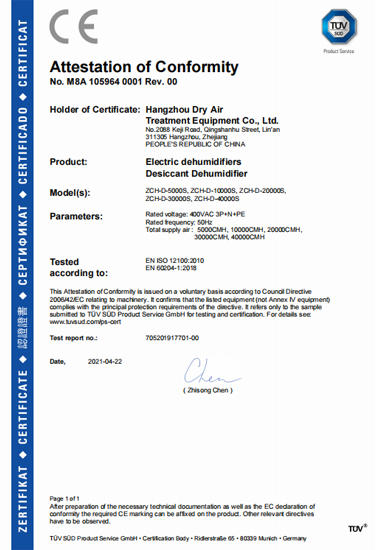

CE Certificate

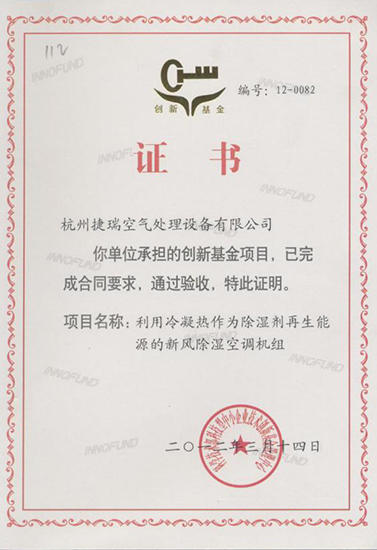

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

The Application of Pharmaceutical Chemicals VOC Organic Waste Gas Treatment

Volatile organic compounds (VOCs) are a group of chemicals that can have harmful effects on human health and the environment. Many pharmaceutical companies use these chemicals in their manufacturing processes, resulting in the release of VOC organic waste gases into the atmosphere.

To address this issue, pharmaceutical companies can implement VOC organic waste gas treatment systems. These systems use various methods to remove or reduce VOCs from the waste gases before they are released into the environment.

One common method is thermal oxidation, which involves heating the waste gases to high temperatures (typically 800-1000°C) to break down the VOCs into less harmful byproducts such as carbon dioxide and water vapor. Another method is adsorption, which involves passing the waste gases through a material (such as activated carbon) that can capture and remove the VOCs.

In addition to these methods, some pharmaceutical companies also use bioreactors to treat their VOC organic waste gases. Bioreactors use microorganisms to break down the VOCs into less harmful substances, such as carbon dioxide and water. This approach can be more sustainable and cost-effective than other methods, as it does not require high temperatures or chemical reagents.

Overall, the application of VOC organic waste gas treatment systems in the pharmaceutical industry is important for reducing the environmental impact of these chemicals and ensuring the safety of workers and the surrounding community.

The production steps of Pharmaceutical Chemicals VOC Organic Waste Gas Treatment

The production of pharmaceutical chemicals can result in the emission of volatile organic compounds (VOCs) and other organic waste gases, which can be harmful to human health and the environment. Therefore, it is important to treat these waste gases before releasing them into the atmosphere. Here are the steps typically involved in treating VOC organic waste gases from pharmaceutical chemical production:

Collection: The first step in treating VOC organic waste gases is to collect them at the source. This is typically done using a system of pipes and hoods that capture the waste gases as they are produced.

Scrubbing: The collected waste gases are then passed through a scrubber system, which uses a liquid solvent to absorb the VOCs and other organic compounds. The solvent is typically a mixture of water and a chemical agent, such as sodium hydroxide or sulfuric acid.

Separation: After passing through the scrubber system, the waste gases and solvent are separated using a series of separators. The solvent is typically recycled for further use in the scrubbing process.

Disposal: The treated waste gases are then released into the atmosphere, typically through a stack or chimney. However, before release, the waste gases may need to be further treated to remove any remaining pollutants or contaminants.

It is important to note that the exact process for treating VOC organic waste gases from pharmaceutical chemical production may vary depending on the specific chemicals being produced, as well as the regulations and guidelines set forth by local, state, and federal authorities.

English

English 简体中文

简体中文

View All

View All