Submit feedback

Shipbuilding VOC Organic Waste Gas Treatment Suppliers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

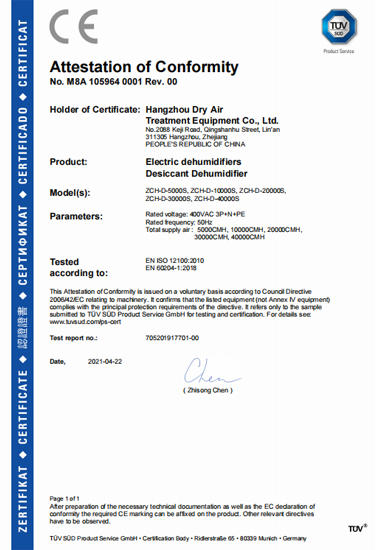

CE Certificate

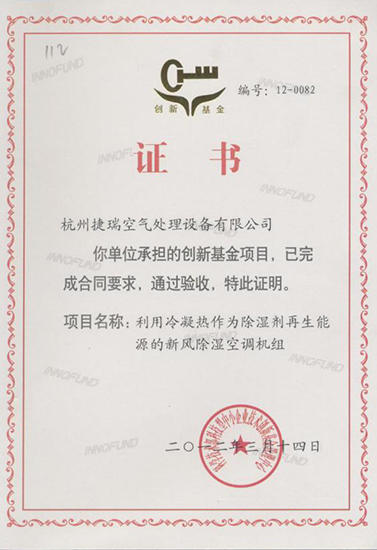

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

How to Choose Shipbuilding VOC Organic Waste Gas Treatment?

When choosing a shipbuilding VOC organic waste gas treatment system, there are several factors that should be taken into consideration:

Type and concentration of VOCs: The type and concentration of VOCs emitted from shipbuilding activities may vary depending on the materials and processes used. It is important to identify the specific VOCs present in the waste gas emissions in order to select a treatment system that is effective in removing these pollutants.

Treatment efficiency: The treatment efficiency of a VOC organic waste gas treatment system is an important factor to consider. The system should be able to remove a high percentage of the VOCs present in the waste gas emissions to ensure that the emissions meet regulatory requirements and do not pose a risk to human health or the environment.

Operating costs: The operating costs of a VOC organic waste gas treatment system should be evaluated to ensure that it is cost-effective for the shipbuilding industry. The costs of energy, maintenance, and replacement parts should be considered when selecting a treatment system.

Size and space requirements: The size and space requirements of the treatment system should be evaluated to ensure that it can be accommodated in the shipbuilding facility. The system should not take up too much space and should be designed to fit the specific requirements of the facility.

Compliance with regulations: The VOC organic waste gas treatment system should comply with local and national regulations for emissions from shipbuilding activities. The system should be designed to meet the specific regulatory requirements in the region where the facility is located.

Reputation of the manufacturer: The reputation and experience of the manufacturer of the VOC organic waste gas treatment system should also be considered. A reputable manufacturer with experience in designing and installing VOC treatment systems for the shipbuilding industry is more likely to deliver a high-quality and reliable treatment system.

In summary, when choosing a shipbuilding VOC organic waste gas treatment system, it is important to consider the type and concentration of VOCs emitted, treatment efficiency, operating costs, size and space requirements, compliance with regulations, and the reputation of the manufacturer.

The Structure of Shipbuilding VOC Organic Waste Gas Treatment

The structure of shipbuilding VOC organic waste gas treatment depends on the specific process and requirements of the shipbuilding operation. However, there are some common components that are often included in the structure of shipbuilding VOC organic waste gas treatment systems:

Exhaust Capture: The first component of the system is the capture of the VOC-laden exhaust gas. This is typically done through the use of hoods, ducts, and fans that capture the waste gas at the source.

Pre-Treatment: After the VOC-laden exhaust gas is captured, it is often subjected to pre-treatment to remove any large particles or impurities that may be present. This can involve the use of filters, scrubbers, or other pre-treatment methods.

Adsorption: The next component of the system is often an adsorption unit, which removes the VOCs from the waste gas. This is typically done through the use of activated carbon or other adsorbent materials that capture the VOCs as the gas passes through the unit.

Thermal Oxidation: After the waste gas is treated with an adsorption unit, it may be subjected to thermal oxidation to remove any remaining VOCs. This involves heating the gas to high temperatures to break down the VOCs into carbon dioxide and water.

Heat Recovery: Many shipbuilding VOC organic waste gas treatment systems include heat recovery components that recover heat generated during the treatment process. This heat can be used to preheat the waste gas or to provide heat for other processes in the shipbuilding operation.

Monitoring and Control: Finally, shipbuilding VOC organic waste gas treatment systems often include monitoring and control components that ensure the system is operating effectively and efficiently. This can involve the use of sensors, controllers, and other monitoring equipment to track the performance of the system and make adjustments as necessary.

Overall, the structure of shipbuilding VOC organic waste gas treatment systems is designed to capture and remove VOCs from the waste gas generated during shipbuilding operations. The specific components of the system will vary depending on the requirements of the operation, but they typically include exhaust capture, pre-treatment, adsorption, thermal oxidation, heat recovery, and monitoring and control components.

English

English 简体中文

简体中文

View All

View All