Submit feedback

Bridges Rotary Dehumidification Unit Suppliers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

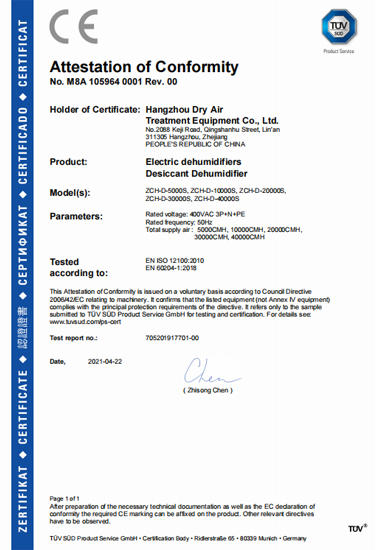

CE Certificate

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

The Application of Bridges Rotary Dehumidification Unit

Bridges are exposed to a variety of weather conditions, which can cause moisture buildup and corrosion. The use of a rotary dehumidification unit can help control the humidity levels and prevent moisture-related damage to the bridge structure. Here are some specific applications of rotary dehumidification units for bridges:

Prevention of Corrosion: Moisture buildup on the bridge structure can lead to corrosion, which can weaken the structure and shorten its lifespan. A rotary dehumidification unit can help reduce the humidity levels on the bridge, which helps prevent corrosion.

Preservation of Historical Bridges: Many bridges are considered historical landmarks and require special preservation efforts to maintain their integrity. A rotary dehumidification unit can help preserve the structure of historical bridges by controlling the humidity levels and preventing corrosion.

Maintenance of Suspension Bridges: Suspension bridges require regular maintenance to ensure their safety and longevity. A rotary dehumidification unit can help control the humidity levels in the bridge's cables, which helps prevent corrosion and damage to the cables.

Reduction of Maintenance Costs: Moisture-related damage to bridges can be expensive to repair. The use of a rotary dehumidification unit can help reduce the need for costly repairs and maintenance, which can save money in the long run.

Protection of Bridge Infrastructure: Moisture buildup on the bridge can also cause damage to the infrastructure, such as electrical systems and roadway surfaces. A rotary dehumidification unit can help protect these important components by controlling the humidity levels and preventing moisture-related damage.

In summary, the application of rotary dehumidification units for bridges is focused on the prevention of moisture-related damage to the structure, preservation of historical bridges, maintenance of suspension bridges, reduction of maintenance costs, and protection of bridge infrastructure. By controlling the humidity levels on the bridge, rotary dehumidification units can help improve the safety, longevity, and integrity of bridge structures.

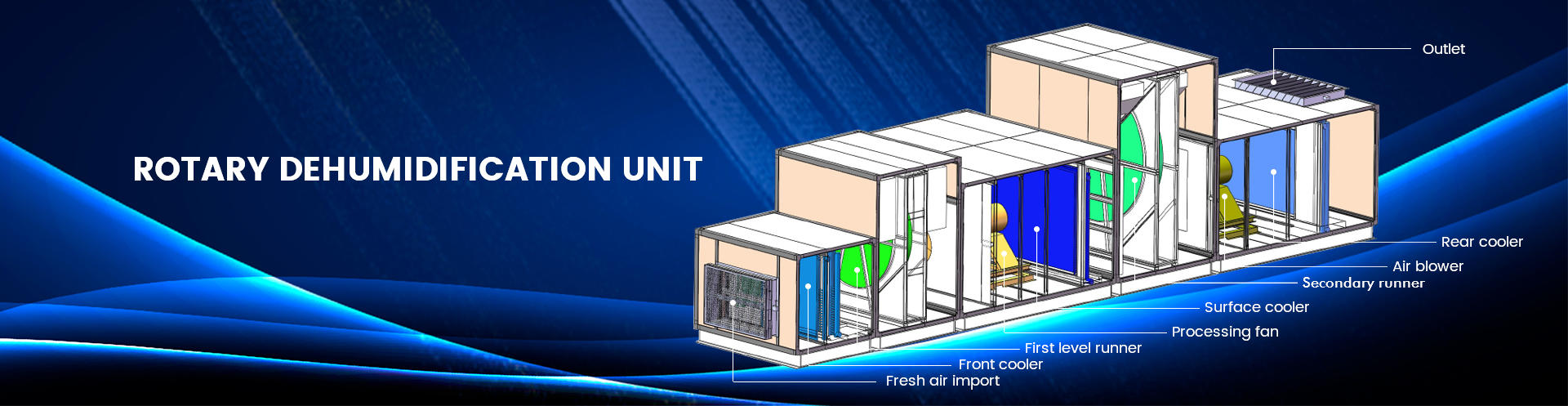

The working principle of Bridges Rotary Dehumidification Unit

Bridges Rotary Dehumidification Unit is a type of dehumidifier that uses a rotating wheel made of a desiccant material to remove moisture from the air. The working principle of this unit can be explained in the following steps:

The process begins with the intake of humid air into the dehumidification unit. The air passes through a filter to remove any impurities and then enters the rotating wheel chamber.

The rotating wheel consists of a desiccant material that has a high affinity for water vapor. As the wheel rotates, the humid air comes in contact with the desiccant material, and the moisture in the air is absorbed by the material.

The air that has been stripped of moisture then exits the unit and is discharged into the environment. Meanwhile, the moisture-laden desiccant material continues to rotate and is heated to release the moisture it has absorbed.

The released moisture is then exhausted out of the dehumidification unit, and the desiccant material is ready to absorb moisture once again.

The process of moisture absorption and release continues as long as the dehumidification unit is in operation.

The Bridges Rotary Dehumidification Unit is an efficient and effective way to remove moisture from the air, and it is often used in industrial and commercial settings where humidity control is critical. The unit's design allows for continuous operation, and it can handle large volumes of air, making it an ideal solution for a variety of applications.

English

English 简体中文

简体中文

View All

View All