Submit feedback

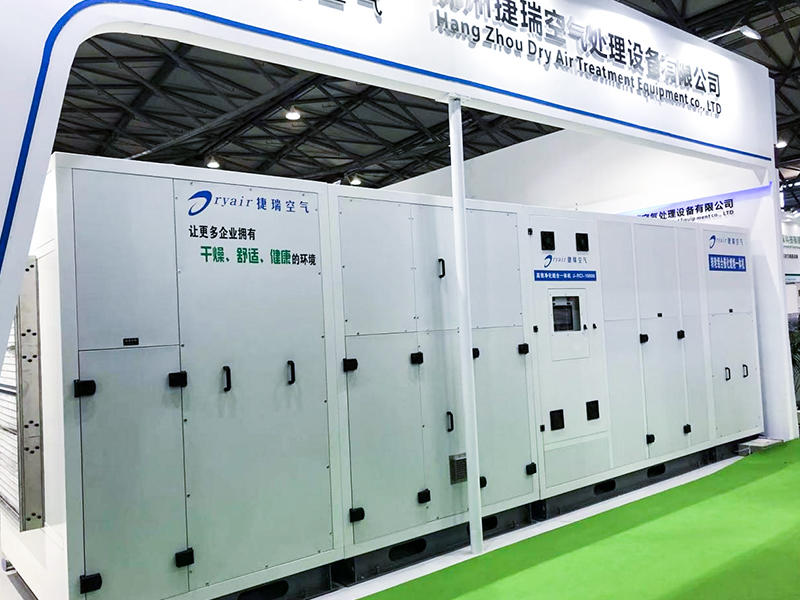

Printing Condensation Recovery Suppliers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

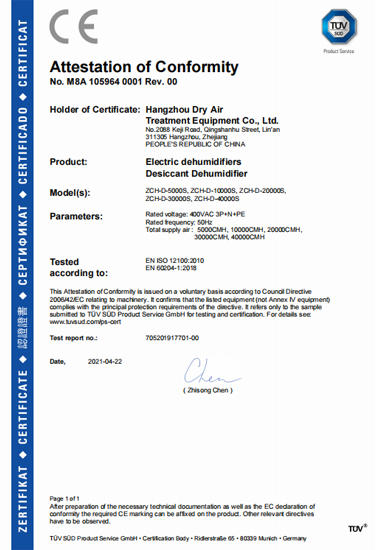

CE Certificate

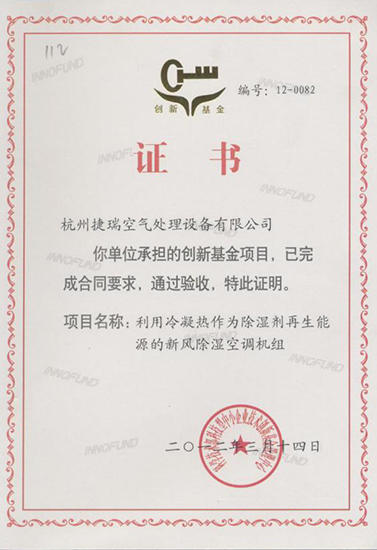

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

What is Printing VOC Organic Waste Gas Treatment?

Printing VOC organic waste gas treatment refers to the process of removing VOCs from the exhaust gases generated by printing operations. VOCs are harmful pollutants that can cause a range of environmental and health problems, including smog, respiratory issues, and cancer.

Printing VOC organic waste gas treatment typically involves using specialized equipment to capture the exhaust gases and then subjecting them to a series of chemical and physical processes that remove the VOCs. These processes can include adsorption, absorption, condensation, and catalytic oxidation. The treated gases can then be safely released into the atmosphere, minimizing their impact on the environment and human health.

There are several types of printing VOC organic waste gas treatment systems available, including thermal oxidizers, catalytic oxidizers, and regenerative thermal oxidizers. The choice of system depends on factors such as the type and concentration of VOCs in the exhaust gases, the volume of gases produced, and the specific requirements of the printing operation.

The Functions of Printing VOC Organic Waste Gas Treatment

Printing VOC (volatile organic compound) organic waste gas treatment systems are designed to capture and treat the emissions generated by printing processes. These emissions can contain a variety of harmful pollutants, including VOCs, particulate matter, and other hazardous chemicals.

The primary functions of printing VOC organic waste gas treatment systems are as follows:

Capture and Control: The system captures the organic waste gas emissions from the printing process and controls their release into the environment. This prevents the release of harmful pollutants into the air and reduces the environmental impact of the printing process.

Purification: The system purifies the captured organic waste gas emissions, removing the harmful pollutants and reducing their concentration to levels that meet regulatory requirements. This ensures that the emissions are safe for release into the environment.

Recycling and Recovery: The system can also be designed to recover and recycle valuable materials from the captured emissions, such as solvents and other chemicals used in the printing process. This can reduce the amount of waste generated by the printing process and provide economic benefits by allowing these materials to be reused.

Energy Recovery: The system can also be designed to recover energy from the captured emissions, such as by using thermal oxidizers or other combustion technologies. This can help to reduce energy consumption and lower operating costs.

Overall, printing VOC organic waste gas treatment systems play a critical role in reducing the environmental impact of printing processes, protecting the health and safety of workers and the public, and improving the sustainability and efficiency of printing operations.

English

English 简体中文

简体中文

View All

View All