Submit feedback

Petrochemicals VOC Organic Waste Gas Treatment Suppliers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

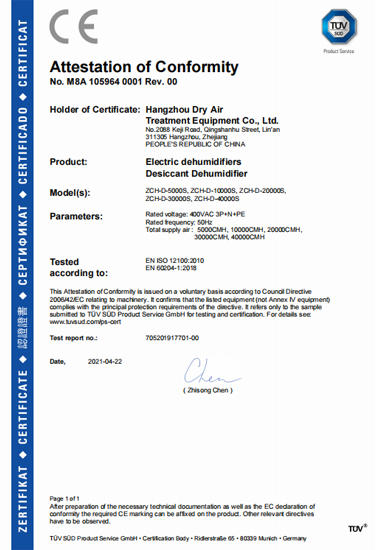

CE Certificate

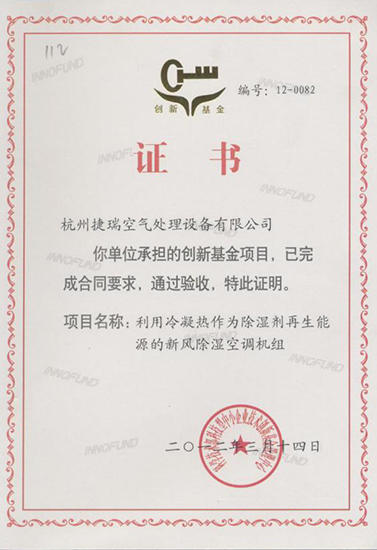

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

The Use of Petrochemicals VOC Organic Waste Gas Treatment

Petrochemicals are chemicals derived from petroleum or natural gas. During the production, storage, and transportation of petrochemicals, volatile organic compounds (VOCs) may be emitted as organic waste gas. These VOCs can have negative impacts on both human health and the environment, such as contributing to air pollution and climate change.

Therefore, it is important to treat petrochemicals VOC organic waste gas to reduce their impact on the environment and human health. There are several methods for treating VOCs, including:

Adsorption: This method involves using materials such as activated carbon or zeolite to adsorb the VOCs from the gas stream. The adsorbed VOCs can then be removed from the adsorbent material through heating or other methods.

Incineration: This method involves burning the VOCs in a high-temperature flame, which converts the VOCs into carbon dioxide and water vapor.

Biofiltration: This method uses microorganisms to break down the VOCs into carbon dioxide and water. The microorganisms are typically grown on a filter bed and the gas stream is passed through the bed, allowing the microorganisms to break down the VOCs.

Catalytic oxidation: This method involves passing the gas stream over a catalyst that helps to break down the VOCs into carbon dioxide and water. This method typically operates at lower temperatures than incineration.

Each of these methods has its advantages and disadvantages depending on the specific application and the concentration of VOCs in the waste gas. It is important to carefully consider the options and select the most appropriate method for treating petrochemicals VOC organic waste gas to minimize their impact on the environment and human health.

How to Choose Petrochemicals VOC Organic Waste Gas Treatment?

Treating petrochemicals VOC (volatile organic compounds) organic waste gas is crucial to prevent air pollution and reduce the potential health and safety risks to workers and the environment. Choosing the right treatment method for VOC organic waste gas requires considering several factors, including:

Type of VOC: Different types of VOCs require different treatment methods. For example, some VOCs are water-soluble, while others are not. The treatment method should be compatible with the type of VOCs present in the waste gas stream.

Concentration and flow rate: The concentration and flow rate of VOC organic waste gas determine the size and type of equipment needed for treatment. High concentrations of VOCs require more advanced treatment methods and larger equipment.

Regulatory compliance: The treatment method chosen should comply with local and federal regulations for emissions control and air quality standards.

Cost: The cost of treatment is a critical factor in determining the most suitable method. The cost should consider the capital investment, operating costs, and maintenance expenses of the treatment system.

Some common treatment methods for petrochemicals VOC organic waste gas include:

Thermal oxidation: This method involves heating the waste gas stream to high temperatures to break down the VOCs into less harmful compounds, such as carbon dioxide and water. This method is effective for high concentrations of VOCs and can achieve high removal efficiency.

Absorption: In this method, the waste gas is passed through a liquid solvent that absorbs the VOCs. The solvent is then regenerated and reused for further treatment. This method is suitable for low to moderate concentrations of VOCs and is cost-effective.

Adsorption: This method involves passing the waste gas through a solid adsorbent material that traps the VOCs. The adsorbent is then regenerated, and the VOCs are recovered for further processing. This method is effective for low concentrations of VOCs and is cost-effective.

Biofiltration: This method uses microorganisms to biodegrade the VOCs in the waste gas stream. The microorganisms are supported on a filter bed, and the waste gas is passed through the bed for treatment. This method is effective for low to moderate concentrations of VOCs and is environmentally friendly.

Catalytic oxidation: This method uses a catalyst to oxidize the VOCs into carbon dioxide and water at lower temperatures than thermal oxidation. This method is effective for low to moderate concentrations of VOCs and is energy-efficient.

In conclusion, choosing the right treatment method for petrochemicals VOC organic waste gas depends on several factors, including the type of VOCs, concentration and flow rate, regulatory compliance, and cost. Consulting with an experienced engineer or environmental consultant can help determine the most appropriate treatment method for specific situations.

English

English 简体中文

简体中文

View All

View All