Submit feedback

Warehouse, Cold Storage Rotary Dehumidification Unit Suppliers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

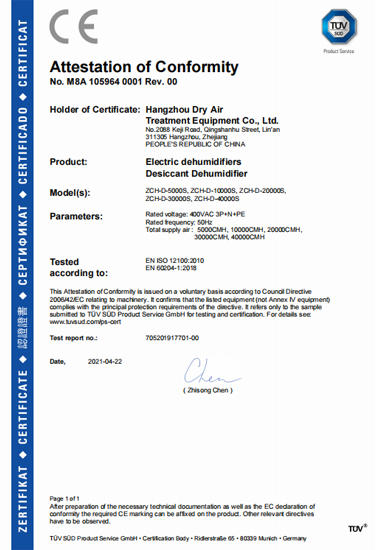

CE Certificate

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

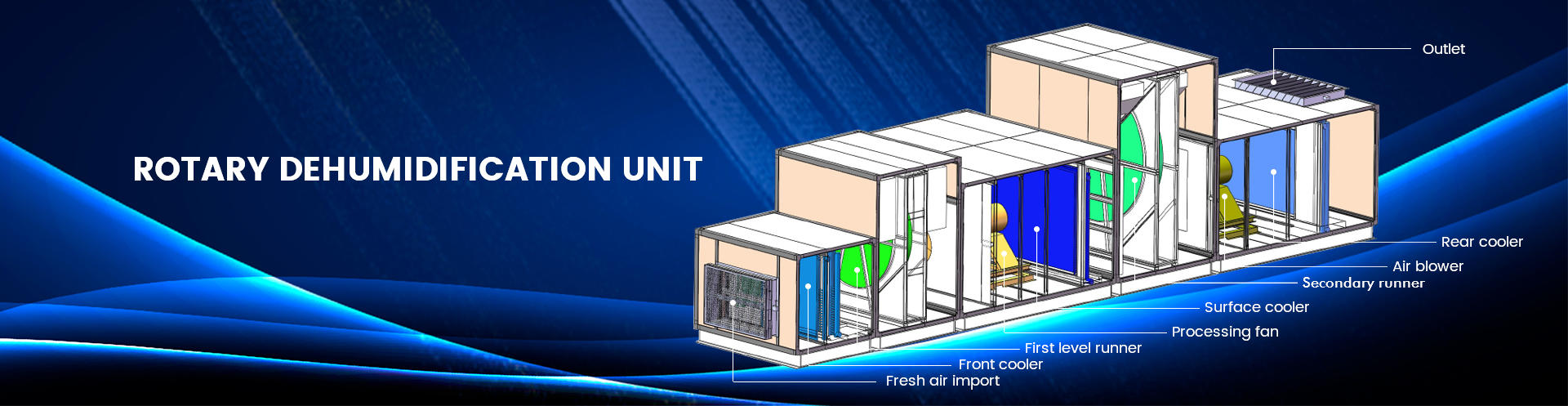

The Classification of cold storage Rotary Dehumidification Unit

Cold storage rotary dehumidification units are classified based on their capacity, construction, and operating conditions. Here are some common types of rotary dehumidification units used in cold storage applications:

Capacity: Rotary dehumidification units are classified based on their capacity to remove moisture from the air. Capacities range from small units suitable for small-scale cold storage facilities to larger units capable of handling the moisture load of large-scale facilities.

Construction: Rotary dehumidification units can be classified based on their construction. This includes the type of materials used, such as aluminum or stainless steel, and whether they are modular or self-contained units. Modular units are typically used in larger facilities, while self-contained units are more common in smaller facilities.

Operating Conditions: Rotary dehumidification units can also be classified based on their operating conditions. For example, some units are designed to operate at lower temperatures, such as those found in freezer storage areas, while others are designed to operate in higher humidity environments.

Energy Efficiency: Another classification method for rotary dehumidification units is based on their energy efficiency. Units that are designed to be energy-efficient can help reduce operating costs and environmental impact. Some models may have additional features, such as variable speed fans and electronic controls, that optimize energy use.

Drainage Method: Rotary dehumidification units can also be classified based on their drainage method. Units may use a gravity drain or require a pump to remove collected moisture. Some models may have built-in pumps, while others may require an external pump.

In summary, cold storage rotary dehumidification units can be classified based on their capacity, construction, operating conditions, energy efficiency, and drainage method. Understanding these classifications can help facilities select the best unit for their specific needs and operating conditions.

The Functions of cold storage Rotary Dehumidification Unit

The rotary dehumidification unit is an essential component of cold storage facilities, as it helps to maintain the required humidity levels inside the storage space. Here are some of the primary functions of the rotary dehumidification unit in a cold storage facility:

Moisture control: The rotary dehumidification unit is responsible for removing excess moisture from the air inside the cold storage space. This is important because high levels of humidity can lead to the growth of mold and bacteria, which can spoil the stored products.

Temperature control: The dehumidification unit also helps to regulate the temperature inside the cold storage space by removing excess moisture. This is important because high humidity levels can cause the temperature inside the storage space to fluctuate, which can lead to spoilage and other problems.

Energy efficiency: The rotary dehumidification unit can help to reduce energy costs in a cold storage facility by reducing the workload on the cooling system. By removing excess moisture from the air, the dehumidification unit can help to maintain the required temperature with less energy.

Product quality: Maintaining the proper humidity levels inside the cold storage space is essential for preserving the quality of the stored products. The rotary dehumidification unit can help to prevent spoilage, reduce odors, and maintain the freshness of the stored products.

Overall, the rotary dehumidification unit plays a critical role in maintaining the optimal environment inside a cold storage facility. By controlling the humidity and temperature levels, it helps to preserve the quality of the stored products and reduce energy costs.

English

English 简体中文

简体中文

View All

View All