Submit feedback

Lithium Battery Production Waste Gas Treatment Suppliers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

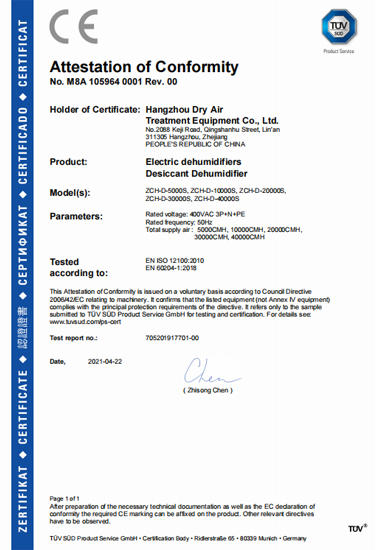

CE Certificate

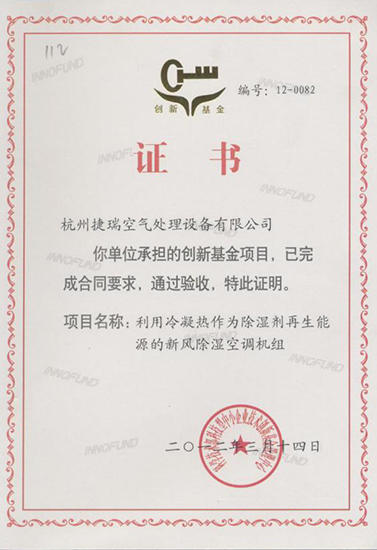

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

The Structure of Lithium battery production VOC Organic Waste Gas Treatment

The production of lithium batteries involves several processes that can generate VOC (volatile organic compound) organic waste gas, which needs to be treated to prevent harm to the environment and human health. The treatment of VOC organic waste gas from lithium battery production typically involves the following steps:

Collection: The waste gas is collected using a ventilation system that captures the gas from the sources of emission such as drying ovens, solvent storage tanks, and coating machines.

Concentration: The collected waste gas is then concentrated using a thermal or adsorption method to increase the concentration of the VOCs in the gas stream.

Combustion: The concentrated waste gas is then sent to a thermal oxidizer where it is burned at high temperatures (800-1200°C) to convert the VOCs into carbon dioxide and water vapor, which are released into the atmosphere.

Scrubbing: In some cases, after the combustion process, the gas stream may be treated with scrubbers to remove any remaining pollutants, such as particulate matter or acid gases, before being released into the atmosphere.

Monitoring: Finally, the treated gas is continuously monitored to ensure that the emissions are within the permitted limits set by the regulatory authorities.

It is important to note that the treatment of VOC organic waste gas from lithium battery production is crucial to minimize the impact on the environment and human health. Proper waste gas treatment also helps companies to comply with environmental regulations and ensure the safety of their employees and the surrounding communities.

How to Install Lithium battery production VOC Organic Waste Gas Treatment?

Installing a VOC organic waste gas treatment system for lithium battery production involves several steps:

Site Assessment: A site assessment is conducted to determine the specific requirements for the installation of the VOC organic waste gas treatment system. This involves evaluating the size of the facility, the number of production lines, and the amount of waste gas generated.

Design and Engineering: Based on the results of the site assessment, a treatment system is designed and engineered to meet the specific needs of the facility. The system should be designed to effectively capture and treat the waste gas, while also minimizing energy consumption and operational costs.

Equipment Selection: The appropriate equipment is selected for the VOC organic waste gas treatment system. This may include a variety of components, such as gas collection hoods, ductwork, fans, scrubbers, and filters.

Installation: The system is installed by experienced professionals who are trained in the installation and maintenance of VOC organic waste gas treatment systems. The installation process should be carefully planned and executed to ensure that the system is properly installed and functioning as intended.

Testing and Commissioning: Once the system is installed, it is tested and commissioned to ensure that it is operating correctly and effectively. This involves testing the system under normal operating conditions to verify that it is achieving the desired levels of air pollution control.

Ongoing Maintenance: Finally, ongoing maintenance is required to ensure that the system continues to operate effectively over time. This involves regular inspections, cleaning, and replacement of components as needed, as well as monitoring of performance to ensure that the system is meeting air pollution control regulations.

English

English 简体中文

简体中文

View All

View All