Submit feedback

Tapes VOC Organic Waste Gas Treatment Suppliers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

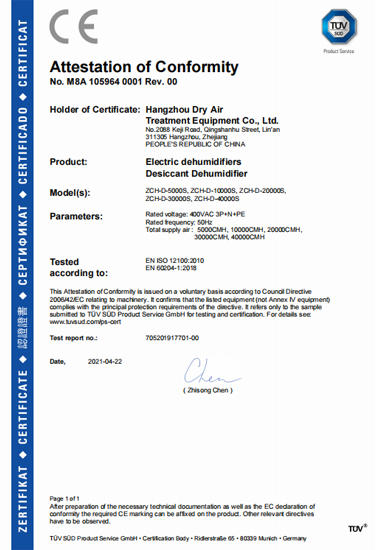

CE Certificate

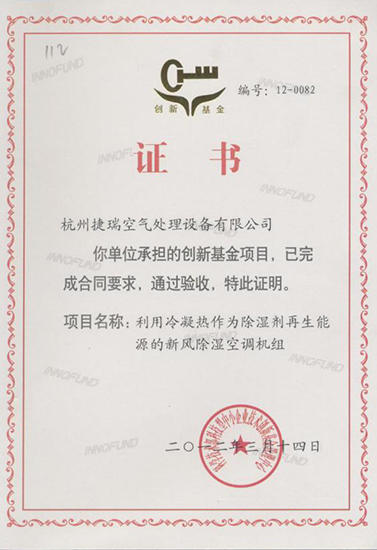

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

The Use of Tapes VOC Organic Waste Gas Treatment

Volatile organic compounds (VOCs) are a group of organic chemicals that have a high vapor pressure at room temperature. These compounds can have adverse effects on human health and the environment, so it's important to control their emissions.

One way to control VOC emissions is through the use of tapes VOC organic waste gas treatment. This method involves using a tape that is impregnated with an activated carbon material. The tape is installed in an air handling system, and as the VOC-laden air passes through the system, the activated carbon in the tape adsorbs the VOCs.

The adsorption process involves the physical binding of the VOCs to the surface of the activated carbon. The activated carbon has a large surface area, which provides ample space for the VOCs to bind. Once the VOCs are adsorbed, they are no longer present in the air stream and are trapped within the tape.

Tape VOC organic waste gas treatment is a simple and effective method for controlling VOC emissions. It's relatively easy to install and maintain, and it doesn't require a lot of energy to operate. However, it's important to note that the tape will eventually become saturated with VOCs and will need to be replaced. The frequency of tape replacement will depend on the concentration of VOCs in the air stream and the volume of air that is being treated.

Overall, tape VOC organic waste gas treatment is a useful tool for controlling VOC emissions in a variety of industries. It's an effective method for reducing the environmental impact of VOC emissions and can help companies comply with regulations governing VOC emissions.

The Structure of Tapes VOC Organic Waste Gas Treatment

The structure of a typical VOC (volatile organic compound) organic waste gas treatment system using tapes is as follows:

Inlet duct: This is the duct through which the waste gas containing VOCs enters the treatment system.

Pre-treatment system: This is where the waste gas is first treated to remove any solid or liquid particles that may be present in the gas stream. This is typically achieved through the use of filters or cyclones.

Adsorption system: This is where the waste gas is passed through a bed of adsorbent material, such as activated carbon or zeolite. The adsorbent material captures the VOCs from the gas stream, effectively removing them from the air.

Desorption system: Once the adsorbent material is saturated with VOCs, it needs to be regenerated to restore its capacity for adsorption. This is typically achieved through heating the adsorbent bed, which causes the VOCs to evaporate and be collected for further treatment or disposal.

Outlet duct: This is the duct through which the treated gas is released back into the atmosphere.

Overall, the tape system in VOC organic waste gas treatment is typically used as a component of an overall system designed to capture and remove VOCs from industrial waste gas streams. The tapes themselves are typically made from a material with high surface area and good adsorption properties, such as activated carbon fibers, and are arranged in a way that maximizes their exposure to the waste gas stream.

English

English 简体中文

简体中文

View All

View All