Submit feedback

Insulation, New Materials Waste Gas Treatment Suppliers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

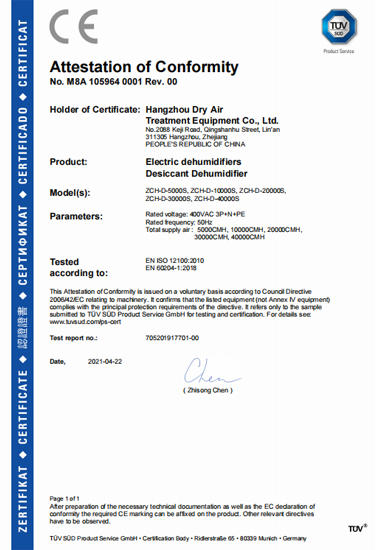

CE Certificate

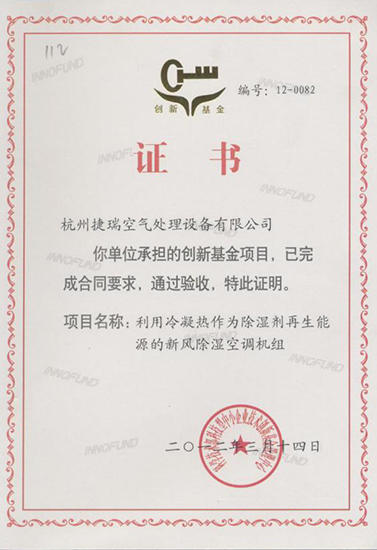

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

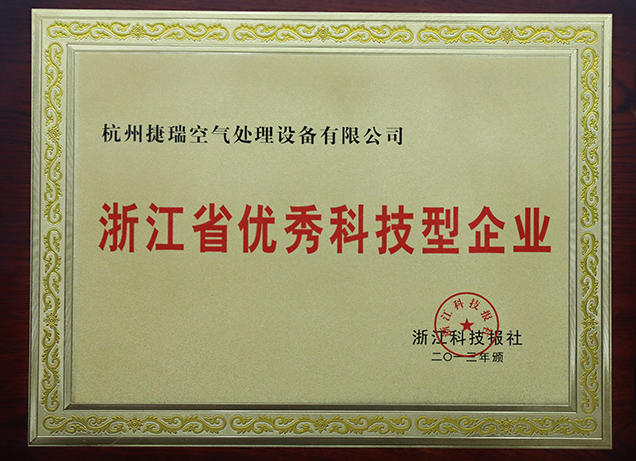

Excellent Science and Technology Enterprise of Zhejiang Province

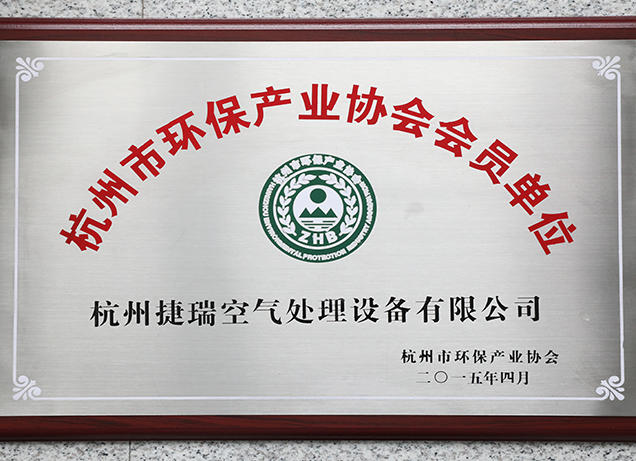

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

The Importance of Insulation VOC Organic Waste Gas Treatment

Insulation is important for maintaining comfortable indoor temperatures and reducing energy consumption. However, some insulation materials can emit volatile organic compounds (VOCs) and other organic waste gases that can negatively impact indoor air quality and human health.

VOCs are emitted by a wide range of building materials, including insulation, paints, adhesives, and cleaning products. These compounds can cause a range of health effects, including respiratory irritation, headaches, dizziness, and even cancer.

In addition to their negative impact on indoor air quality, VOCs also contribute to outdoor air pollution and can harm the environment.

To address these issues, it is important to use insulation materials that have low VOC emissions and to properly ventilate buildings to prevent the buildup of indoor air pollutants. It is also important to properly dispose of any waste insulation materials to prevent the release of harmful gases into the environment.

Organic waste gas treatment can also be used to reduce the emissions of VOCs and other organic waste gases from industrial processes. Treatment methods can include thermal oxidation, catalytic oxidation, and adsorption. These methods can help to improve air quality and reduce the environmental impact of industrial processes.

Overall, it is important to consider the impact of insulation and other building materials on indoor and outdoor air quality, and to take steps to reduce emissions of harmful pollutants.

The Structure of Insulation VOC Organic Waste Gas Treatment

The structure of an insulation VOC (Volatile Organic Compound) organic waste gas treatment system typically consists of the following components:

Inlet Duct: The inlet duct connects the source of the VOC emissions to the treatment system. This duct is usually made of metal and is designed to withstand the temperature and pressure of the gas stream.

Pre-treatment System: The pre-treatment system is designed to remove any solid or liquid particles from the gas stream before it enters the main treatment system. This can include filters or cyclones to remove larger particles or a scrubber system to remove smaller particles and droplets.

Adsorption System: The adsorption system is the main component of the treatment system and is designed to remove the VOCs from the gas stream. This can include one or more beds of activated carbon or other adsorbent materials that can capture the VOC molecules.

Exhaust Duct: The exhaust duct carries the treated gas stream from the treatment system to the atmosphere. This duct is also made of metal and is designed to withstand the temperature and pressure of the gas stream.

Monitoring System: The monitoring system includes sensors and instruments that measure the concentration of VOCs in the gas stream before and after treatment. This is important to ensure that the treatment system is operating effectively and to provide feedback for process control.

Control System: The control system includes the electronic and mechanical components that control the operation of the treatment system. This can include a programmable logic controller (PLC), a user interface for monitoring and control, and safety interlocks to protect the system and personnel.

Emergency System: The emergency system includes safety devices such as pressure relief valves, fire suppression systems, and gas detectors that are designed to protect the treatment system and personnel in the event of an emergency.

The specific design and configuration of an insulation VOC organic waste gas treatment system will depend on a number of factors, including the type and concentration of VOCs in the gas stream, the flow rate and temperature of the gas stream, and the local environmental regulations. A qualified engineer should be consulted to design a system that meets the specific requirements of the application.

English

English 简体中文

简体中文

View All

View All