Submit feedback

Food Industry Dehumidifier Suppliers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

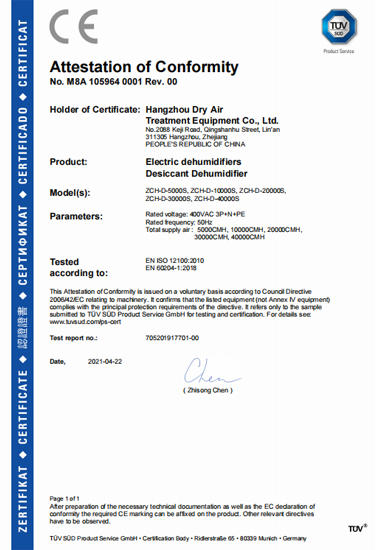

CE Certificate

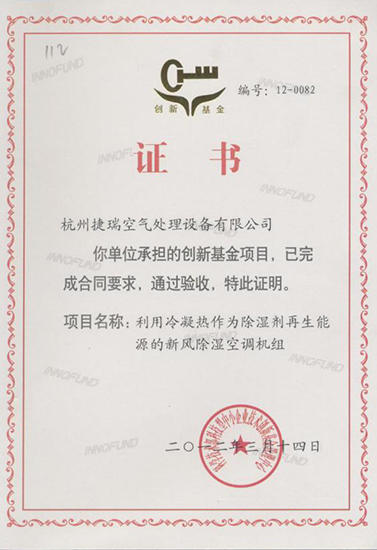

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

The working principle of Food Industry Dehumidifier

The working principle of a food industry dehumidifier is similar to that of a standard dehumidifier. The dehumidifier pulls in humid air from the surrounding environment and passes it over a refrigerated coil. The coil causes the moisture in the air to condense into droplets, which are collected and drained away, leaving behind drier air.

However, food industry dehumidifiers are designed to meet specific requirements for use in food processing and storage environments. These units are typically made with food-grade materials and are designed to prevent the growth of bacteria and other microorganisms.

Food industry dehumidifiers may also include additional features, such as filters or UV lights, to further purify the air and prevent the growth of contaminants.

In addition to removing excess moisture from the air, food industry dehumidifiers can also help to regulate temperature and air circulation, improving the overall environment for food processing and storage.

Overall, the working principle of a food industry dehumidifier is simple: it removes excess moisture from the air, helping to prevent spoilage and maintain product quality in food processing and storage environments.

The production steps of Food Industry Dehumidifier

Food industry dehumidifiers are designed to remove moisture from the air in food processing facilities, storage rooms, and other areas where humidity control is important. Here are the typical production steps for a food industry dehumidifier:

Design and engineering: The first step is to design the dehumidifier based on the specific requirements of the food industry application. The design includes selecting the appropriate materials, components, and features such as humidity control, temperature control, air filtration, and energy efficiency.

Manufacturing of components: The various components of the dehumidifier, such as the compressor, evaporator, condenser, fan, and control panel, are manufactured according to the specifications of the design.

Assembly: The components are then assembled into the dehumidifier unit. This process includes installing the compressor, evaporator, condenser, fan, and control panel into a housing unit.

Quality control: The assembled unit is then subjected to quality control tests to ensure it meets the manufacturer's standards and performance specifications. These tests may include electrical testing, refrigerant testing, and functional testing.

Packaging and shipping: Once the dehumidifier passes quality control testing, it is packaged and prepared for shipping to the customer. The unit is typically packed with protective materials and includes a user manual, warranty information, and installation instructions.

Installation and maintenance: Upon delivery, the dehumidifier is installed by a qualified technician according to the manufacturer's instructions. Regular maintenance is required to ensure optimal performance and longevity of the unit.

In conclusion, the production steps of a food industry dehumidifier involve design and engineering, manufacturing of components, assembly, quality control, packaging, shipping, and installation/maintenance. The resulting product is a high-quality dehumidifier that is specifically designed for the unique needs of the food industry.

English

English 简体中文

简体中文

View All

View All