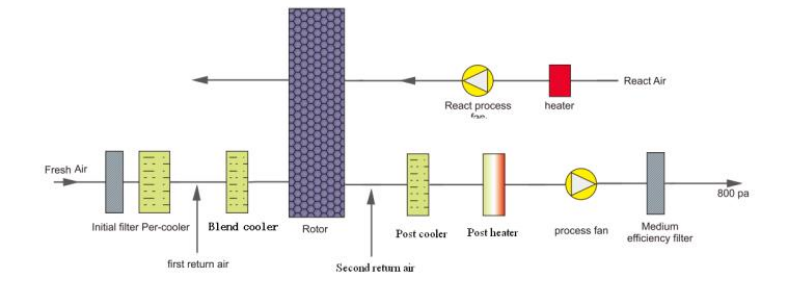

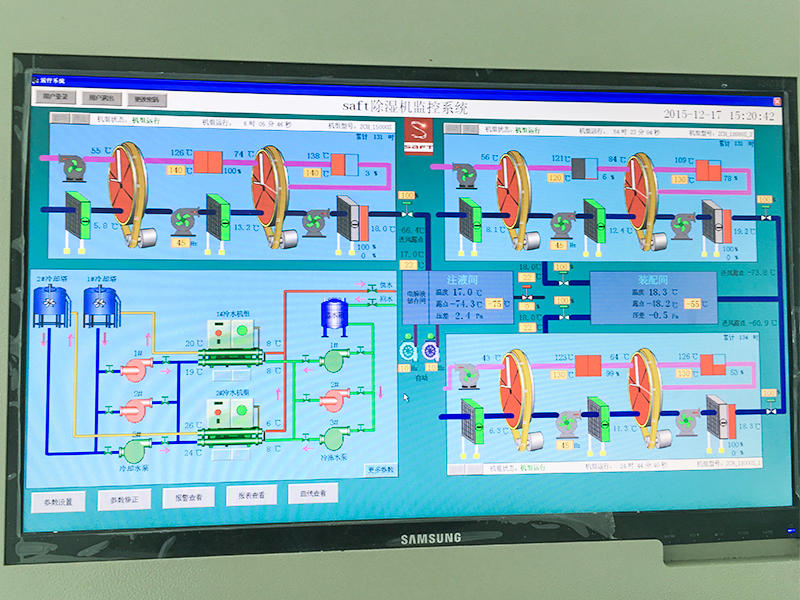

Process Flow Chart:

Product Features:

● Patented energy-saving technology;

● Electric and steam heated regenerative heaters are available;

● Aluminum alloy frame with anti-cold bridge, small size light weight and good sealing

● Modular assembly, easy for quick installation.

Humidity Control:

10~40%RH

Technical parameters reference:

|

ZCB SERIES COMBINED DESICCANT DEHUMIDIFIER |

||||||||||||

|

Model/Project |

Rotor air volume m3/h |

Unit air supply volume m3/h |

Outlet residual pressure |

Regenerative air volume m3/h |

Regenerative energy consumption |

Installed power distribution (kw) |

Freezing water volume(7℃) |

Unit weight(kg) |

||||

|

Electrical power(kw) |

Steam volume(kg/h) |

Steam pipe diameter |

Electrical regeneration |

Steam regeneration |

t/h |

Water pipe diameter |

||||||

|

ZCB-D/Z20-2000 |

2000 |

2000 |

≥300 |

600 |

20 |

40 |

DN20 |

23.05 |

3.05 |

5 |

DN40 |

1150 |

|

ZCB-D/Z30-3000 |

3000 |

3000 |

900 |

30 |

60 |

DN20 |

34.2 |

4.2 |

10 |

DN40 |

1450 |

|

|

ZCB-D/Z40-4000 |

4000 |

4000 |

1200 |

40 |

80 |

DN25 |

45.2 |

5.2 |

12 |

DN40 |

1600 |

|

|

ZCB-D/Z50-5000 |

5000 |

5000 |

1500 |

50 |

100 |

DN25 |

57.1 |

7.1 |

15 |

DN50 |

1800 |

|

|

ZCB-D/Z60-6000 |

6000 |

6000 |

1800 |

60 |

120 |

DN25 |

67.1 |

7.1 |

20 |

DN50 |

2000 |

|

|

ZCB-D/Z80-8000 |

8000 |

8000 |

2400 |

80 |

160 |

DN25 |

89.8 |

9.8 |

25 |

DN50 |

2200 |

|

|

ZCB-D/Z100-10000 |

10000 |

10000 |

3000 |

100 |

200 |

DN25 |

113.3 |

13.3 |

30 |

DN65 |

2400 |

|

|

ZCB-D/Z120-12000 |

12000 |

12000 |

3600 |

120 |

240 |

DN25 |

134.2 |

14.2 |

35 |

DN65 |

2700 |

|

|

ZCB-D/Z150-15000 |

15000 |

15000 |

4500 |

150 |

300 |

DN25 |

170.7 |

20.7 |

45 |

DN65 |

2700 |

|

|

ZCB-D/Z200-20000 |

20000 |

20000 |

6000 |

200 |

400 |

DN32 |

224.2 |

24.2 |

60 |

DN80 |

3000 |

|

|

ZCB-D/Z250-25000 |

25000 |

25000 |

7500 |

250 |

500 |

DN32 |

279.7 |

29.7 |

75 |

DN80 |

3300 |

|

1. Within 30% fresh air ratio design.

2. Outside air calculated as 35℃/75% RH.

3. Control humidity range of 10-40%.

4. The residual pressure of the treated air ≥ 550Pa.

5. Regeneration air residual pressure ≥ 300Pa.

6. Steam pressure ≥ 0.4MPa.

7. Three-phase 380V / 50HZ as standard design power supply.

8. Customization as per user's requirements.

|

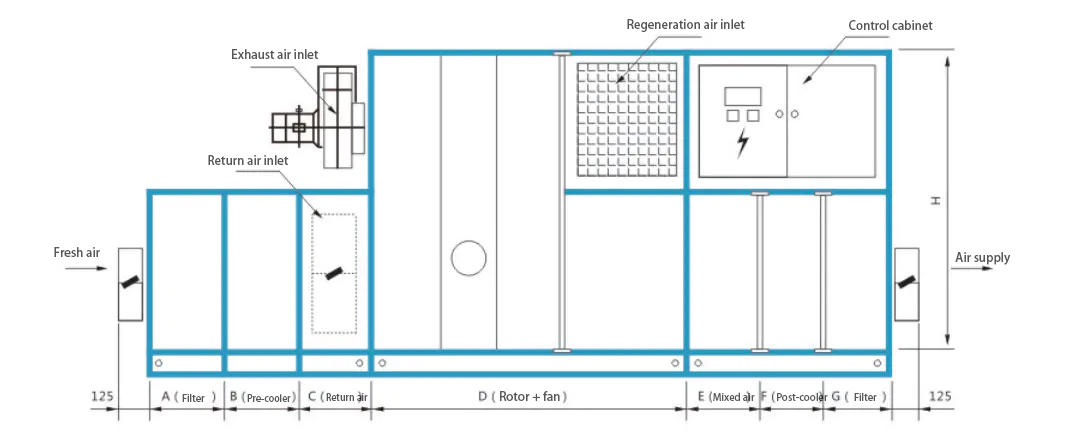

ZCB series combined rotor dehumidifier unit functional section size table |

||||||||||||||

|

Model |

Whole machine section size mm |

Inlet air filtration section mm |

Pre-stage surface cooling section mm |

Return air section mm |

Rotor + fan section mm |

Mixed air section mm |

Rear surface cooling + heating mm |

Outlet Air Filtration mm |

Length of the unit mm |

New Windfall mm |

Process air vents mm |

Regeneration air inlet mm |

Regenerative air outlet mm |

|

|

WxH |

A |

B |

C |

Cross-section size |

D |

E |

F |

G |

J |

|||||

|

WxH |

||||||||||||||

|

ZCB-D/Z20-2000 |

1220×1370 |

450 |

700 |

400 |

1630×2150 |

1050 |

400 |

500+200 |

500 |

5100 |

250×200 |

300×250 |

400x300 |

360x185 |

|

ZCB-D/Z30-3000 |

1370×1470 |

450 |

700 |

400 |

1630×2150 |

1050 |

400 |

500+200 |

500 |

5100 |

300×250 |

400×300 |

550x350 |

360x185 |

|

ZCB-D/Z40-4000 |

1370×1470 |

550 |

700 |

500 |

1630×2150 |

1150 |

500 |

500+200 |

500 |

5100 |

400×300 |

500×300 |

550x400 |

360x185 |

|

ZCB-D/Z50-5000 |

1520×1770 |

550 |

700 |

500 |

1750×2250 |

1150 |

500 |

500+200 |

500 |

5700 |

400×300 |

500×400 |

550x450 |

360x185 |

|

ZCB-D/Z60-6000 |

1520×1770 |

550 |

700 |

500 |

1750×2250 |

1150 |

500 |

500+200 |

500 |

5700 |

400×300 |

600×400 |

650x450 |

400x210 |

|

ZCB-D/Z80-8000 |

1520×1770 |

550 |

700 |

500 |

1750×2250 |

1150 |

500 |

500+200 |

500 |

5850 |

500×400 |

600×500 |

750x500 |

400x210 |

|

ZCB-D/Z100-10000 |

1770×1970 |

550 |

700 |

500 |

1850×2300 |

1250 |

500 |

500+200 |

500 |

5850 |

600×500 |

800×500 |

750x550 |

450x230 |

|

ZCB-D/Z120-12000 |

1770×1970 |

550 |

700 |

600 |

1850×2300 |

1250 |

600 |

500+200 |

500 |

6000 |

600×500 |

800×500 |

800x500 |

450x230 |

|

ZCB-D/Z150-15000 |

2070×2315 |

550 |

700 |

600 |

2070×2350 |

1350 |

600 |

500+200 |

500 |

6150 |

800×500 |

1000×500 |

800x550 |

500x255 |

|

ZCB-D/Z200-20000 |

2070×2315 |

550 |

700 |

600 |

2070×2350 |

1450 |

600 |

500+200 |

500 |

6150 |

800×600 |

1000×600 |

850x550 |

500x255 |

|

ZCB-D/Z250-25000 |

2370×2570 |

550 |

700 |

600 |

2370×2570 |

1450 |

600 |

500+200 |

500 |

6450 |

1000×600 |

1000×800 |

850x650 |

500x255 |

Design Note:

1. The above models need to provide ≤ 7 ℃ chilled water as required, if necessary, we can also provide refrigeration units with their own refrigeration systems as required.

2. Each functional section and process flow can be customized according to user requirements, other specifications or special requirements are also welcome to request;

3. Reserve the right to change technology or design.

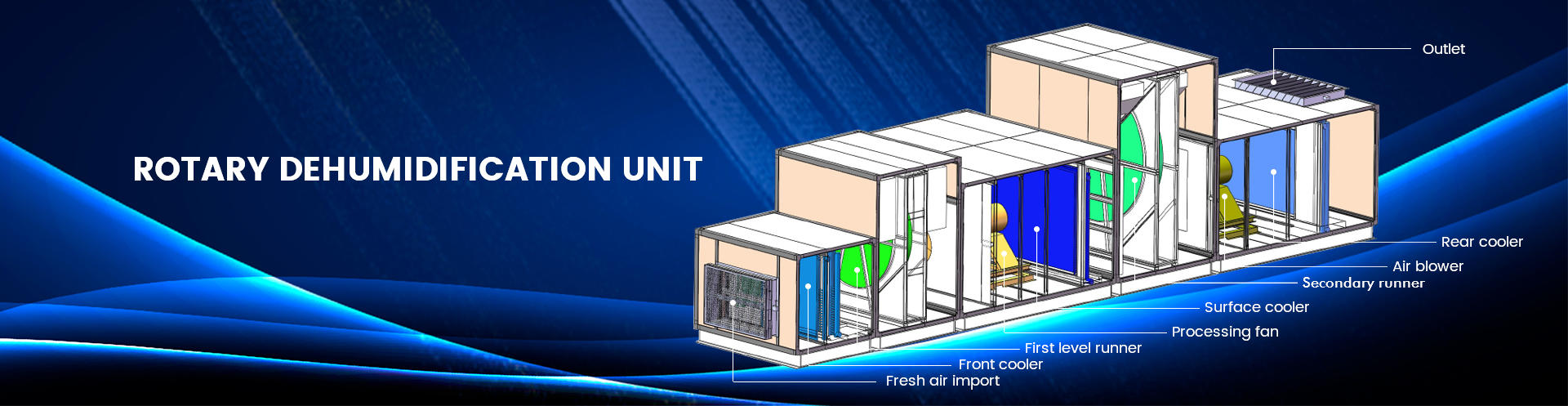

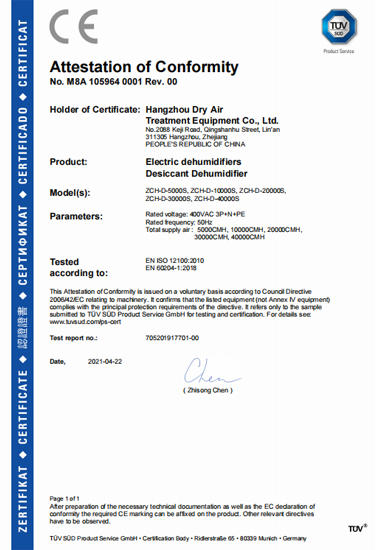

ZCB SERIES Combined Desiccant Dehumidifiers Widely used in glass, pharmaceutical, chemical, food, rubber, and fertilizer manufacturing; any process/material affected by moisture.

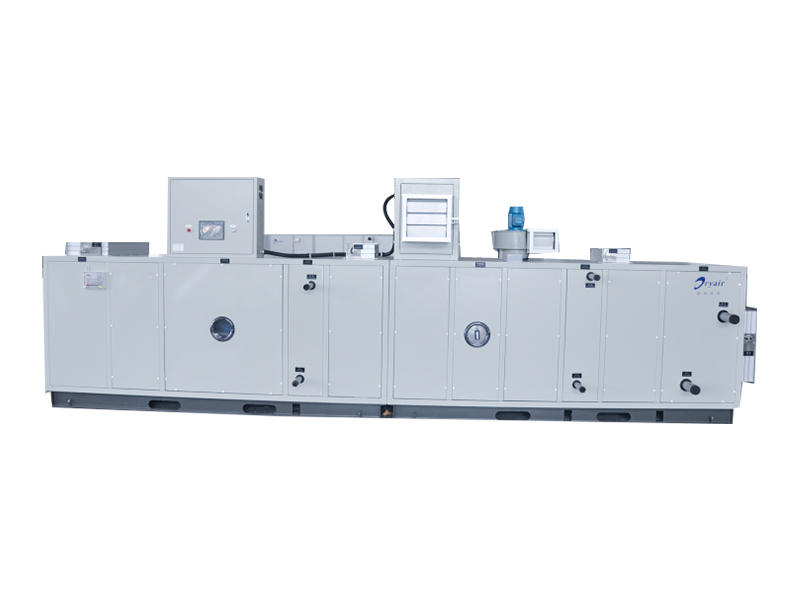

ZCB series Combined Desiccant Dehumidifiers incorporate many advanced features including an innovative double wall construction structure with superior air tightness and good insulation performance. Surface options of panels including galvanized steel, aluminum alloy, stainless steel or any combination permit an effective choice for all kinds of operational environments.

ZCB series Combined Desiccant Dehumidifiers are especially suitable for manufacturing process with humidity requirement from 10% to 40% at normal temperature.

ZCB series Combined Desiccant Dehumidifiers can be customized to meet almost any requirements.Standard options of this series units include desiccant wheel, process fan,reactivation fan, reactivation heater, reactivation filter, pre-cooler, blend-cooler, post-cooler, heating coil for winter, G4 pre-filter ,medium filter and optional HEPA(high efficiency particulate air),air cooled or water cooled condensing unit ,chilled water piping, air duct system,PLC control system which can provide full temperature and humidity controls.

English

English 简体中文

简体中文

View All

View All