Submit feedback

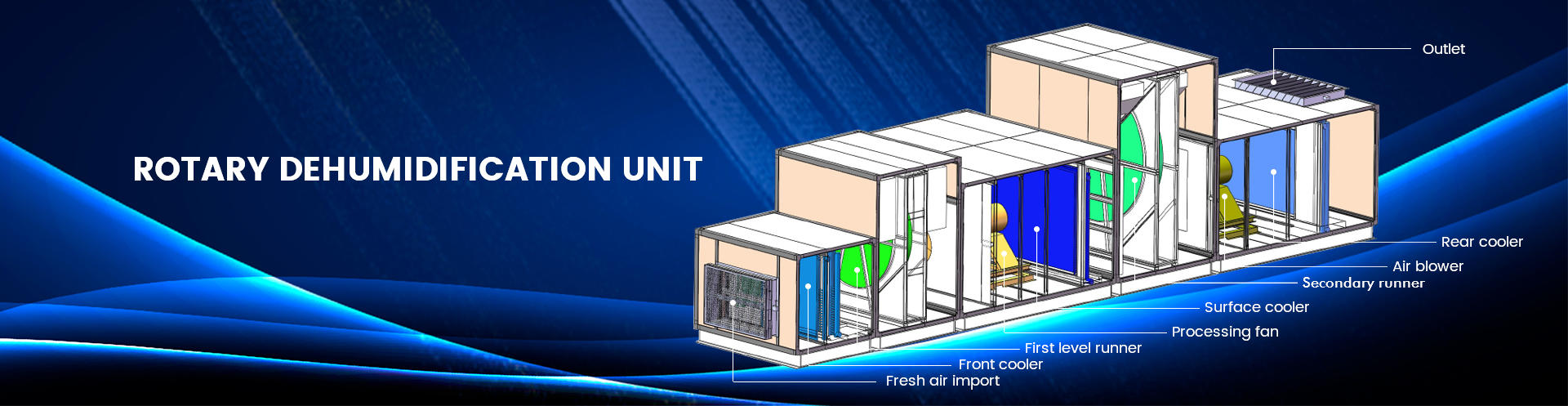

Rotary Dehumidification Unit Manufacturers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

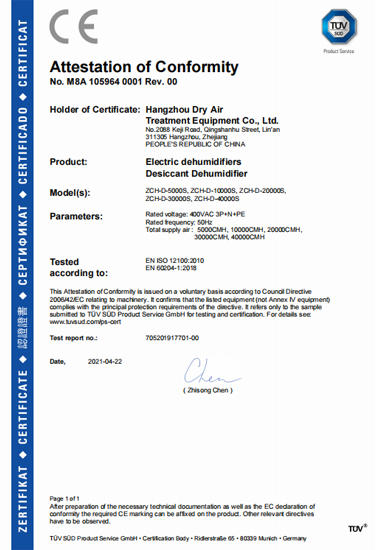

CE Certificate

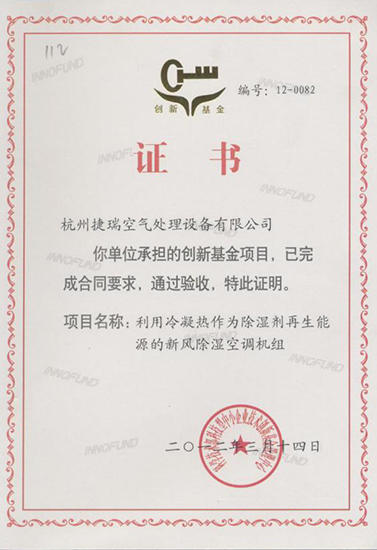

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

How to Install Rotary Dehumidification Unit?

Installing a rotary dehumidification unit can be a complex process, so it is important to follow the manufacturer's instructions carefully. Here are some general steps to guide you through the process:

Choose a suitable location: The unit should be placed in a well-ventilated area with adequate space for air circulation. It should be away from walls and other obstructions to allow for proper airflow.

Mount the unit: The unit should be securely mounted to the wall or ceiling using appropriate brackets and screws. Make sure the unit is level.

Connect the power supply: The unit should be connected to a power source according to the manufacturer's instructions. It is recommended to have a licensed electrician perform this step.

Connect the drainage system: The dehumidifier will generate condensate, which needs to be drained away. Connect the drainage hose according to the manufacturer's instructions, making sure it is positioned to allow water to flow freely.

Test the unit: Once everything is installed, turn on the unit and test it to make sure it is functioning properly. Check for any leaks in the drainage system and ensure that the unit is removing moisture from the air.

Regular maintenance: To ensure optimal performance and longevity, it is important to follow the manufacturer's recommended maintenance schedule. This may include cleaning the filter, checking the drainage system for blockages, and inspecting the unit for any damage.

It is important to note that rotary dehumidification units are complex pieces of equipment, and installation should be performed by a qualified professional. If you are unsure about any aspect of the installation process, consult with the manufacturer or a licensed contractor.

The Application of Rotary Dehumidification Unit

Rotary dehumidification units are commonly used in a variety of applications where precise humidity control is required. Here are some examples of where rotary dehumidification units may be used:

Indoor pool facilities: Indoor pools require careful humidity control to prevent damage to the building structure and equipment, as well as to maintain a comfortable environment for swimmers. Rotary dehumidification units can help to control humidity levels in these spaces.

Food processing facilities: Many food processing facilities require very low humidity levels to prevent spoilage and maintain product quality. Rotary dehumidification units can help to remove excess moisture from the air, reducing the risk of microbial growth and spoilage.

Museums and archives: Artwork, artifacts, and documents can be damaged by high levels of humidity, so many museums and archives use rotary dehumidification units to maintain a stable, low-humidity environment. This helps to preserve these valuable items for future generations.

Pharmaceutical manufacturing: Many pharmaceutical products are sensitive to moisture and require low humidity environments during production and storage. Rotary dehumidification units can help to control humidity levels in manufacturing facilities and storage areas.

Data centers: High humidity levels can damage sensitive computer equipment and lead to data loss. Rotary dehumidification units can help to maintain a low-humidity environment in data centers, reducing the risk of equipment failure and data loss.

Greenhouses: High humidity levels in greenhouses can promote the growth of mold and other harmful organisms, leading to plant disease and reduced crop yields. Rotary dehumidification units can help to maintain optimal humidity levels for plant growth and prevent the spread of disease.

These are just a few examples of the many applications where rotary dehumidification units may be used. In general, any application that requires precise humidity control can benefit from the use of rotary dehumidification technology.

English

English 简体中文

简体中文

View All

View All