Submit feedback

Electrician VOC Organic Waste Gas Treatment Suppliers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

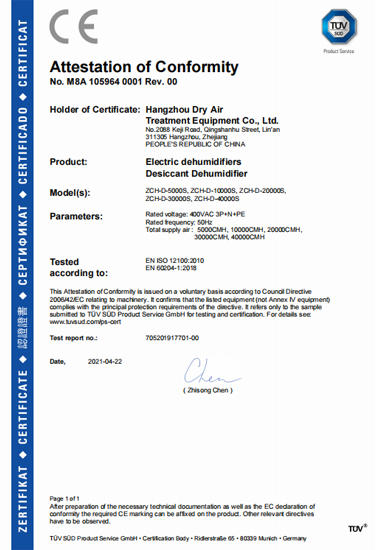

CE Certificate

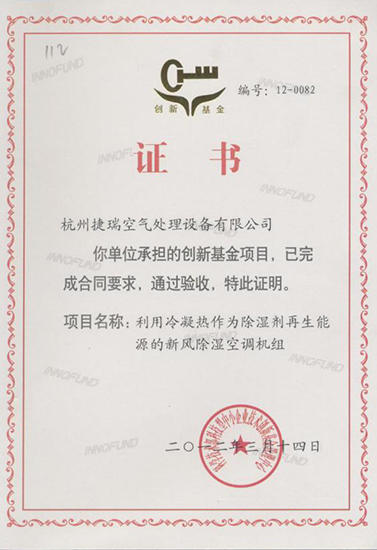

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

The production steps of Electrician VOC Organic Waste Gas Treatment

Electrician VOC organic waste gas treatment typically involves the following production steps:

Collection: The first step is to collect the VOC organic waste gas from the source. This can be done using a variety of methods, including vacuum suction, exhaust hoods, and ductwork.

Adsorption: The collected VOC organic waste gas is then passed through an adsorption system, which typically uses activated carbon or other adsorbent materials to capture the VOCs from the gas stream. This process effectively removes the VOCs from the gas stream, leaving clean air to be released into the environment.

Desorption: Once the adsorbent material is saturated with VOCs, it needs to be regenerated. The desorption process typically involves heating the adsorbent material, which causes the VOCs to evaporate and be released from the material. The evaporated VOCs are then collected and sent for further treatment or disposal.

Condensation: The desorbed VOCs are typically in a gaseous state and need to be condensed to a liquid state for further treatment or disposal. This is typically done using a condenser, which cools the gas stream to a temperature where the VOCs condense into a liquid.

Treatment: Once the VOCs are condensed into a liquid state, they can be treated using a variety of methods, depending on the specific VOCs involved. Treatment methods can include oxidation, biodegradation, and physical-chemical processes.

Disposal: Finally, the treated VOCs can be disposed of safely and in compliance with local regulations. This can involve recycling the VOCs for use in other processes or sending them to a hazardous waste disposal facility.

Overall, the production steps of electrician VOC organic waste gas treatment are designed to effectively remove VOCs from industrial processes, prevent harmful emissions, and protect the environment.

How to Install Electrician VOC Organic Waste Gas Treatment?

The installation of an Electrician VOC (Volatile Organic Compound) organic waste gas treatment system typically involves the following steps:

Site Preparation: The installation site should be prepared in accordance with the requirements of the Electrician VOC system manufacturer. This may include leveling the site, providing adequate space for the system, and ensuring that the site has appropriate electrical and plumbing connections.

Unpacking and Inspection: Once the site is prepared, the Electrician VOC system should be unpacked and inspected for any damage that may have occurred during shipping.

Mounting the System: The Electrician VOC system should be mounted on a stable platform, such as a concrete pad or steel frame, to prevent movement during operation. The manufacturer's instructions should be followed for proper mounting and alignment.

Electrical Connections: The Electrician VOC system will require electrical connections to power the blower and other components. A licensed electrician should be consulted to ensure that all electrical connections are properly made and meet local electrical codes.

Plumbing Connections: The Electrician VOC system will also require plumbing connections to supply and discharge water for the scrubber system. The manufacturer's instructions should be followed for proper installation and connection of the plumbing.

Testing and Commissioning: Once the system is installed and all connections have been made, the Electrician VOC system should be tested and commissioned to ensure that it is operating correctly. This may include testing the blower, scrubber system, and monitoring sensors to ensure that they are functioning properly.

Training and Documentation: Finally, personnel who will be operating and maintaining the Electrician VOC system should be trained in its operation and maintenance procedures. All installation and operating documentation should be reviewed and maintained for future reference.

It is important to note that the installation of an Electrician VOC system should be performed by qualified professionals who have experience with the installation and operation of similar systems. Proper installation is critical to ensure that the system operates effectively and safely.

English

English 简体中文

简体中文

View All

View All