Submit feedback

Gas Station Waste Gas Treatment Suppliers

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

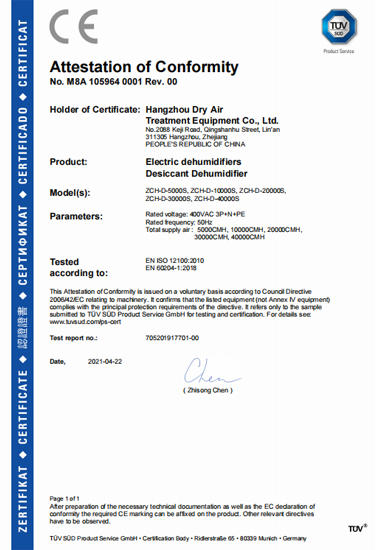

CE Certificate

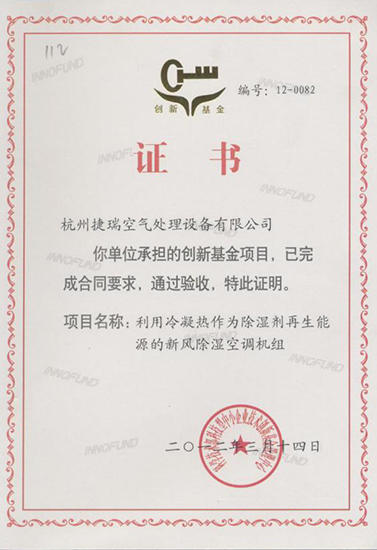

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

-

What effect does thermal conductivity have on lithium battery dry chamber efficiency?

Thermal conductivity significantly affects the efficiency of lithium battery dry rooms. Thermal conductivity refers to the ability of a substance to transfer heat, determining the ...

2024-03-19 -

What does the dry efficiency of lithium battery drying room mainly depend on?

The drying efficiency of lithium battery dry rooms mainly depends on several aspects, which collectively determine the speed, effectiveness, and energy utilization efficiency of th...

2024-03-12 -

How does the lithium battery dry room help the development of the new energy automobile industry?

Lithium battery dry rooms play a crucial role in the development of the new energy vehicle industry. Here are several key aspects in which lithium battery dry rooms contribute to t...

2024-03-05 -

How can the design of the NMP Solvent Recovery System be customized to accommodate changes in process requirements in different industries?

The design of an NMP solvent recovery system can be customized to accommodate changes in process requirements across different industries by considering various factors related to ...

2024-02-26 -

What are the components of the NMP Solvent Recovery System and what roles do they play?

The NMP solvent recovery system comprises several key components, each serving a specific role in the recovery process. These components work together to efficiently remove NMP sol...

2024-02-23

The Application of Gas Station VOC Organic Waste Gas Treatment

Gas stations emit volatile organic compounds (VOCs) from fueling operations and evaporation of fuel. These VOCs can be harmful to human health and the environment. Therefore, gas station VOC organic waste gas treatment is essential to prevent the negative effects of these pollutants.

One common method of gas station VOC organic waste gas treatment is through the use of activated carbon adsorption systems. These systems work by passing the waste gas through a bed of activated carbon, which adsorbs the VOCs from the gas stream. The treated gas is then released into the atmosphere, while the adsorbed VOCs are periodically removed and disposed of.

Another method of gas station VOC organic waste gas treatment is through thermal oxidizers. These systems use high temperatures to oxidize the VOCs, converting them into carbon dioxide and water vapor, which are released into the atmosphere. Thermal oxidizers can be used for larger gas stations with higher VOC emissions.

Gas station VOC organic waste gas treatment provides several benefits, including:

Protection of human health: VOCs emitted from gas stations can cause respiratory problems and other health issues. By treating these pollutants, gas station VOC organic waste gas treatment can help to protect workers and nearby communities from the harmful effects of these pollutants.

Environmental protection: VOCs can contribute to smog and other air pollution, as well as contribute to climate change. By treating these pollutants, gas station VOC organic waste gas treatment can help to reduce the environmental impact of gas stations and promote sustainability.

Compliance with regulations: Many countries and regions have regulations in place that require gas stations to treat their waste gas emissions. By implementing gas station VOC organic waste gas treatment, gas station owners can comply with these regulations and avoid fines or other penalties.

Overall, gas station VOC organic waste gas treatment is an important step towards ensuring responsible and sustainable gas station operations. By minimizing the impact of gas station emissions, we can create a healthier and more sustainable future.

The Structure of Gas Station VOC Organic Waste Gas Treatment

The structure of gas station VOC organic waste gas treatment can vary depending on the specific requirements of the facility and the pollutants present in the waste gas. However, a typical system may include the following components:

Gas collection hood: This is the point of capture for the waste gas that is emitted during fueling operations and evaporation of fuel. The gas collection hood is positioned close to the source of emissions and designed to capture the waste gas.

Ductwork: The ductwork transports the waste gas from the gas collection hood to the treatment system. The ductwork may be made of metal or plastic and may include dampers to regulate the flow of waste gas.

Pre-treatment system: The pre-treatment system is designed to remove large particles and other contaminants from the waste gas before it enters the main treatment system. This may include a cyclone separator or a filter.

Treatment system: The treatment system is the heart of the waste gas treatment process. It is designed to remove the VOCs from the waste gas using a variety of methods, including activated carbon adsorption or thermal oxidation. The specific type of treatment system used will depend on the type and concentration of pollutants present in the waste gas.

Exhaust stack: The treated waste gas is then discharged into the atmosphere through an exhaust stack. The height of the stack is designed to ensure that the waste gas is dispersed high enough in the atmosphere to prevent any negative impacts on human health or the environment.

Control system: The control system is responsible for regulating the entire waste gas treatment process. It may include sensors to monitor the concentration of pollutants in the waste gas, as well as valves and other equipment to control the flow of waste gas and treatment chemicals.

Overall, the goal of a gas station VOC organic waste gas treatment system is to ensure that the waste gas is properly captured, treated, and released in a way that minimizes its impact on the environment and human health. By implementing a well-designed gas station VOC organic waste gas treatment system, gas station owners can help to protect workers, nearby communities, and the environment from the harmful effects of VOC emissions.

English

English 简体中文

简体中文

View All

View All