Submit feedback

Reflective Material Coating Waste Gas Treatment Suppliers

Hangzhou Dry Air Intelligent Equipment Co., LTD is a professional and . With a world-class team of research and development, marketing and service engineers, we have been researching and developing cutting-edge technology in environment and air treatment industry, our products are widely used in aviation, environmental protection, lithium battery, food, architecture, pharmaceutical, and many other industries, moreover, we have experience of providing integrated solutions and technical support for large satellite launch base, important cabin of Chinese Navy vessels, Chinese Army's warehouses. The company which was founded in 2004, is located in Qingshan science and technology industrial zone in the west of Hangzhou, covers an area of 25000 square meters and has more than 200 staff.

Company Honors

Zhejiang manufacturing certificate

Certificate of Integration of Informatization and Industrialization

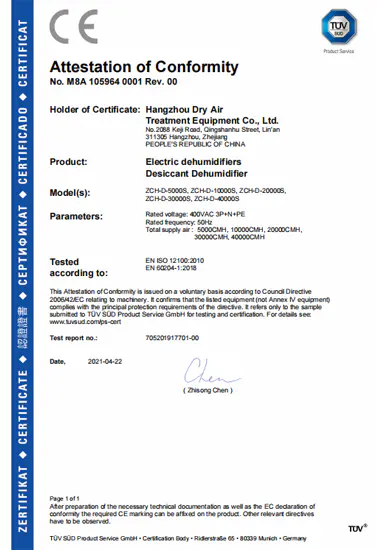

CE Certificate

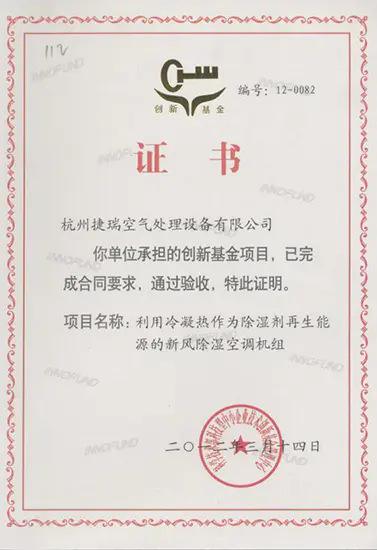

Innovation Fund

Refrigeration and air conditioning industry governing unit

Specialized and Specialized

Excellent Science and Technology Enterprise of Zhejiang Province

Member of Hangzhou Environmental Protection Industry Association

Excellent cooperation unit

ZJU Cooperation

Outstanding Innovation Unit

Key Incubatees

Industry knowledge

is a type of coating that is applied to surfaces to increase their reflectivity, which can help to reduce energy costs by reflecting sunlight and heat away from buildings or other structures. VOC organic waste gas treatment, on the other hand, is a process that is used to remove volatile organic compounds (VOCs) from organic waste gases.

English

English 简体中文

简体中文

View All

View All