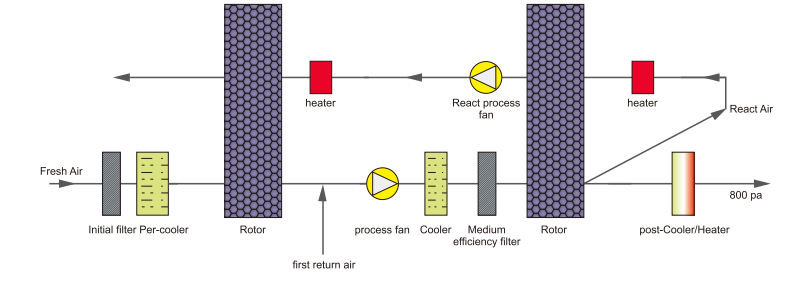

Process Flow Chart:

Applications:

The working principle and process characteristics of batteries, such as the production of lithium-ion batteries, thermal batteries and lithium materials, must be completed in a very dry environment. Ultra-low humidity dehumidification equipment in this production process, it is also an indispensable part, and its dehumidification and drying performance directly affects the electrical performance and safety of the battery.

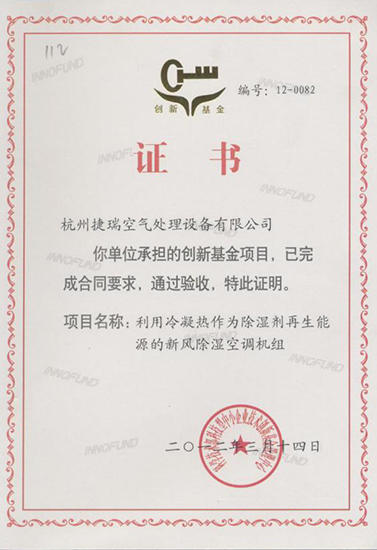

ZCH series low dew point desiccant dehumidifier after years of application and verification in battery-related production processes, can fully meet the environmental needs of battery-related production processes.

Humidity control:

1% RH or below -35℃ DP

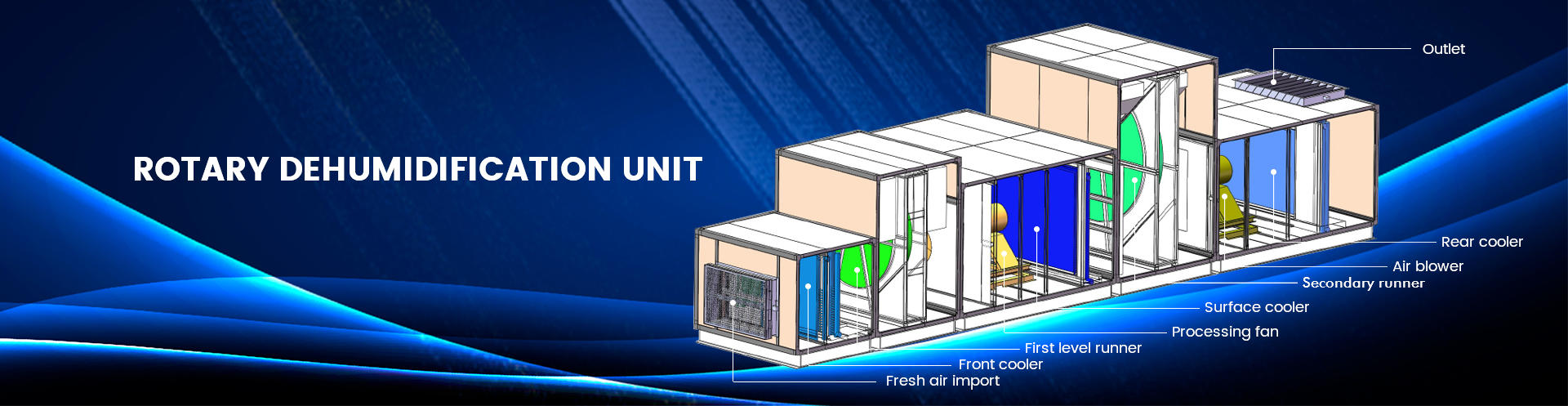

Product Structure:

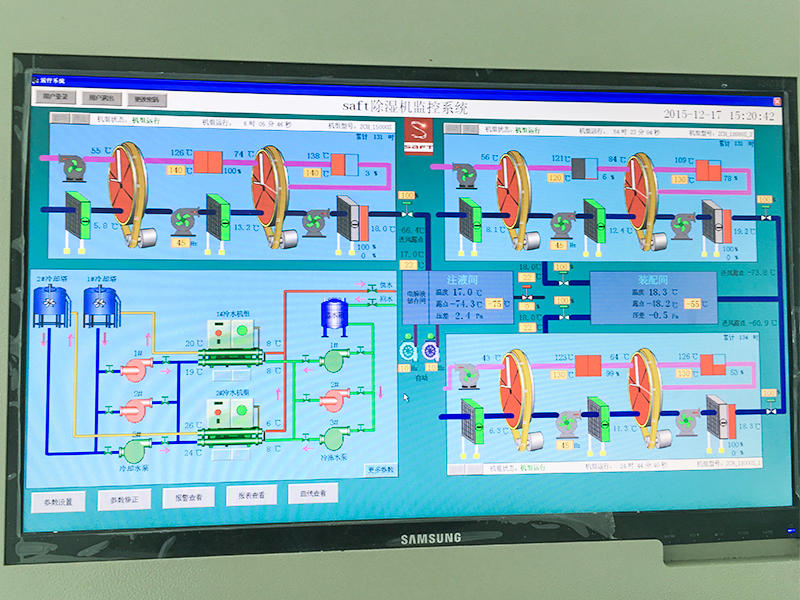

The main components of ZCH series low dew point rotary dehumidifier consists of Primary and medium efficiency fitter section, fresh air surface cooling section, return air surface cooling section, super silica gel or molecular sieve rotor dehumidification section, post surface cooling section, air supply section, regeneration system and PLC control system (optional), etc.

Low humidity dry system project

Turnkey project including drying room

We provide pre-sales, in-sales and after-sales services including consulting, design, production, installation, commissioning and system maintenance.

ZCH series low dew point desiccant dehumidifiers technical parameters table return air type (no corrosive media volatilization in the dry room)

|

ZCH Series Low Dew Point Desiccant dehumidifier(with return air) |

||||||||||||

|

Item |

Process air volume CMH |

Supply air prarmeters |

External Static Pressure(Pa) |

Reactivation energy consumption |

Rated power (kw) |

Required cooling capacity(kw) |

Size(L*W*H) |

Weight (kg) |

||||

|

Electric (kw) |

Steam(kg/h) |

Electrical Reactivated |

Steam Reactivated |

L(mm) |

W(mm) |

H(mm) |

||||||

|

ZCH-D/Z-2000S |

2000 |

T:15~25℃ Td:-60℃

|

200 |

10 |

20 |

12.95 |

2.95 |

30 |

3830 |

1130 |

1920 |

1200 |

|

ZCH-D/Z-3000S |

3000 |

200 |

15 |

30 |

19.1 |

4.1 |

45 |

4000 |

1450 |

2300 |

1500 |

|

|

ZCH-D/Z-4000S |

4000 |

200 |

20 |

40 |

25.1 |

5.1 |

60 |

4300 |

1300 |

2300 |

1800 |

|

|

ZCH-D/Z-5000S |

5000 |

300 |

25 |

50 |

32 |

7 |

75 |

4400 |

1500 |

2600 |

2000 |

|

|

ZCH-D/Z-6000S |

6000 |

300 |

30 |

60 |

37 |

7 |

90 |

4400 |

1500 |

2750 |

2200 |

|

|

ZCH-D/Z-8000S |

8000 |

300 |

40 |

80 |

49.7 |

9.7 |

120 |

7700 |

1800 |

2110 |

2500 |

|

|

ZCH-D/Z-10000S |

10000 |

300 |

50 |

100 |

63.2 |

13.2 |

150 |

7900 |

1800 |

2110 |

2700 |

|

|

ZCH-D/Z-13000S |

13000 |

400 |

65 |

130 |

79 |

14 |

200 |

7900 |

2100 |

2400 |

3000 |

|

|

ZCH-D/Z-15000S |

15000 |

400 |

75 |

150 |

93 |

18 |

230 |

7700 |

2200 |

2400 |

3500 |

|

|

ZCH-D/Z-20000S |

20000 |

400 |

100 |

200 |

124 |

24 |

300 |

8100 |

2400 |

2600 |

4000 |

|

|

ZCH-D/Z-25000S |

25000 |

500 |

125 |

250 |

152.5 |

27.5 |

380 |

8700 |

2500 |

2900 |

4500 |

|

|

ZCH-D/Z-30000S |

30000 |

500 |

150 |

300 |

185.5 |

35.5 |

450 |

9000 |

3000 |

3200 |

5000 |

|

|

ZCH-D/Z-35000S |

35000 |

500 |

175 |

350 |

210.7 |

35.7 |

525 |

9000 |

3000 |

3200 |

5500 |

|

Design Note:

1. 20%-30% fresh air ratio design

2. Environmental parameters are designed according to the temperature of 35 ℃ and relative humidity of 75%

3. Control humidity range of 0.1-2%

4. Regeneration of residual air pressure ≥ 300Pa

5. Steam pressure ≥ 0.4MPa

6. The standard design power supply is three-phase 380V / 50HZ

7. Accept customization according to user needs

ZCH series low dew point rotor desiccant dehumidifiers technical parameters table all fresh air type (dry room with corrosive media volatilization)

|

Model |

Air volume process m3/h |

Supply air prarmeters |

Residual pressure outside the machine(Pa) |

Reactivation energy consumption |

Installed power distribution (kw) |

Required cooling capacity(kw) |

Dimension(L*W*H) |

Weight (kg) |

||||

|

Electric(kw) |

Steam(kg/h) |

Electrical Reactivated |

Steam Reactivated |

Length(mm) |

Width(mm) |

Height(mm) |

||||||

|

ZCH-D/Z-1500X |

1500 |

T: 15~25℃ |

200 |

15 |

30 |

17.35 |

2.35 |

58 |

3830 |

1130 |

1920 |

1000 |

|

ZCH-D/Z-2000X |

2000 |

200 |

20 |

40 |

23 |

3 |

77 |

3850 |

1100 |

2000 |

1200 |

|

|

ZCH-D/Z-3000X |

3000 |

200 |

30 |

60 |

33.75 |

3.75 |

117 |

4000 |

1450 |

2300 |

1500 |

|

|

ZCH-D/Z-4000X |

4000 |

200 |

40 |

80 |

46.7 |

6.7 |

156 |

4300 |

1300 |

2300 |

1800 |

|

|

ZCH-D/Z-5000X |

5000 |

300 |

50 |

100 |

57.5 |

7.5 |

195 |

4400 |

1500 |

2600 |

2000 |

|

|

ZCH-D/Z-6000X |

6000 |

300 |

60 |

120 |

68.5 |

8.5 |

235 |

4400 |

1500 |

2750 |

2200 |

|

|

ZCH-D/Z-8000X |

8000 |

300 |

80 |

160 |

88.5 |

8.5 |

313 |

7700 |

1800 |

2110 |

2500 |

|

|

ZCH-D/Z-10000X |

10000 |

300 |

100 |

200 |

112.5 |

12.5 |

392 |

7900 |

1800 |

2110 |

2700 |

|

|

ZCH-D/Z-13000X |

13000 |

400 |

130 |

260 |

143.2 |

13.2 |

510 |

7900 |

2100 |

2400 |

3000 |

|

|

ZCH-D/Z-15000X |

15000 |

400 |

150 |

300 |

168.3 |

18.3 |

589 |

7700 |

2200 |

2400 |

3500 |

|

|

ZCH-D/Z-20000X |

20000 |

400 |

200 |

400 |

224.3 |

24.3 |

784 |

8100 |

2400 |

2600 |

4000 |

|

|

ZCH-D/Z-23000X |

23000 |

500 |

230 |

460 |

257.8 |

27.8 |

856 |

8700 |

2500 |

2900 |

4500 |

|

|

ZCH-D/Z-26000X |

26000 |

500 |

260 |

520 |

295.5 |

35.5 |

1022 |

9000 |

3000 |

3200 |

5000 |

|

|

ZCH-D/Z-30000X |

30000 |

500 |

300 |

600 |

335.5 |

35.5 |

1176 |

9500 |

3300 |

3300 |

5500 |

|

Design Note:

1. 100% fresh air ratio design

2. Environmental parameters are designed according to the temperature of 35 ℃ and relative humidity of 75%

3. Control humidity range of 0.1-2%

4. Regeneration of residual air pressure ≥ 300Pa

5. Steam pressure ≥ 0.4MPa

6. The standard design power supply is three-phase 380V / 50HZ

7. Accept customization according to user needs

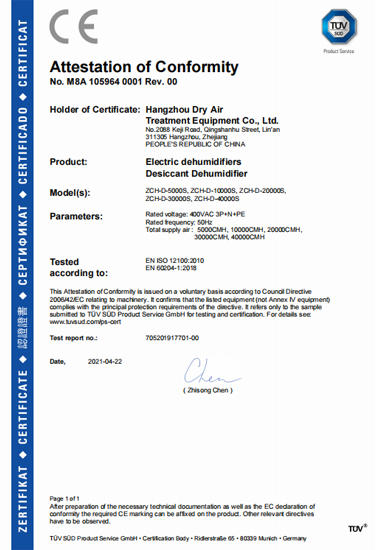

ZCH-SERIES Low Dew Point Desiccant Dehumidifiers

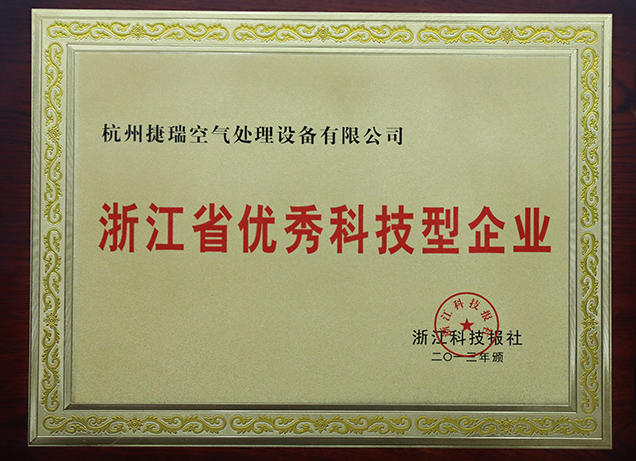

According to work principle and technical characteristics of various batteries, some batteries should be manufactured under very dry circumstance, such as lithium ion batteries, thermo electrical batteries and lithium material and so on. So super low moisture dehumidify equipment is indispensably in the process of manufacturing above batteries or materials. Capability and security of the batteries is directly affected by dehumidifying capacity of the dehumidifier. Hangzhou Dryair Treatment Equipment initiatively developed first low dew point dehumidifying unit for battery industry in 1998, and can provide outfit engineering at the same time. ZCH series low dew point dehumidifying units being used and examined in the above application for many years, has been proved entirely comply with the manufacturing technology, cost-saving and can increase economic benefit.

ZCH series Low Dew Point desiccant dehumidifiers consist of cooling coils, silica gel or molecule sieve rotor ,process fan, reactivation fan, reactivation heater, microcomputer control system and so on.

Our company can also provide outfit engineering including building of drying room. The Dry Room fabrication include transitional room,partition boards with sandwiched pre-painted steel surface and polyurethane foam insulation material filling. It has advantages of compact structure, good air tightness, and excellent heat and moisture resistance properties. The floor is coated by self-leveling epoxy flooring which also has good moisture-resistance features. The drying room is also equipped with purified lamp, power socket, switches, doors and windows. To ensure least air leakage, special design of transitional room, supply air and return air ducts is applied to the system.

Our company provide pre-service, on-sale and after-service system integration outfit engineering including consultation, design, manufacturing, installing, debugging and system maintenance.

English

English 简体中文

简体中文

View All

View All